Six steps to predictive maintenance.

Take your operation to the next level

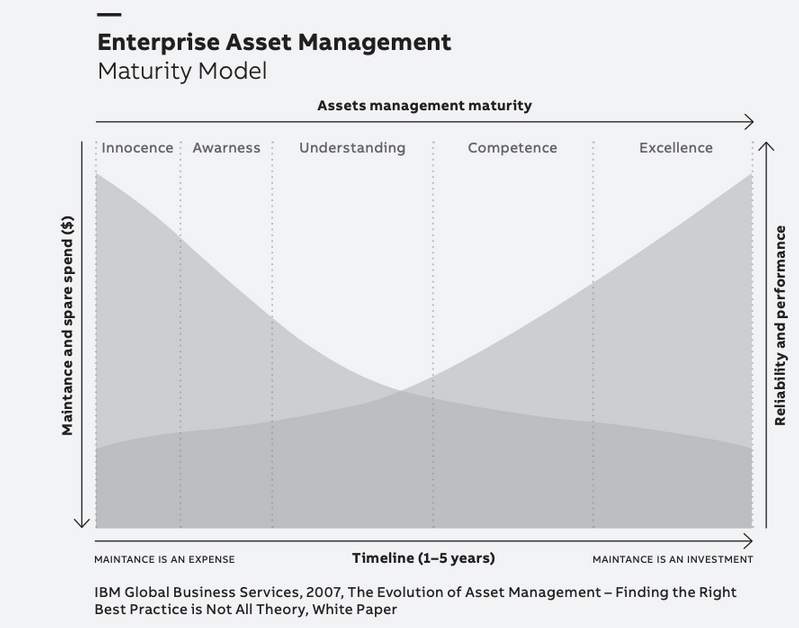

Plotting the path to a predictive maintenance future

The manufacturing sector is facing a myriad of challenges, but they all point in one direction – improving the bottom-line performance. Within the energy sector, one of the most important drivers is to increase operational efficiency. Asset management is key to achieving this. Traditionally assets are large and costly, with long service lives. To achieve high operational efficiency and availability means ensuring that all assets are performing at peak performance with high availability and the lowest possible maintenance costs.

The strategies adopted by companies to manage their assets have evolved over the years but never has the pace of change been so dramatic and profound. Fuelled by the proliferation of accurate low cost sensors, improved high-speed communications, powerful computing including cloud and edge, machine learning and advanced analytics, operating companies are provided assets with some compelling options. When backed up by extensive domain expertise that allows the strategy to be customized to match all the operating requirements perfectly, the pathway to more significant asset optimization and increased operational efficiency can be plotted with confidence.

Many maintenance strategies have been well documented to appropriately manage assets. The traditional scenario includes routine planned maintenance that is typically carried out at the intervals suggested by, among other things, the Original Equipment Manufacturer (OEM). When managed correctly, preventative maintenance has been scheduled by time or some performance parameter, but if not implemented successfully, it turns into a reactive fail and fix scenario that can be disruptive

The cost of adopting the wrong strategy

Despite the wealth of opportunities, many companies in the process industry and energy sectors are still using reactive and preventative maintenance regimes across their asset base. These companies are spending money on time-based maintenance even though it has been shown in various research that preventative maintenance is only appropriate for around 18 percent1 of equipment on plants. Conducting preventative maintenance on the other 82 per cent of asset types can actually introduce failures in themselves.

Clearly there is no one size fits all when it comes to maintenance. The optimum way forward is for companies to evaluate where they are in the Asset Performance Management journey and then choose the right types of strategies for each asset or equipment type, based on the operating scenario of each plant, the role of each piece of equipment, how it might fail and how critical it is to the overall process performance or plant availability

Armed with that information along with the cost of repair and failure, it becomes possible to put the appropriate systems in place. By looking at the strategy from a system perspective, in terms of software and technology, people and process, the most appropriate regime for managing the assets in the most cost-effective and efficient way will come to life. The key is to deploy predictive maintenance on assets where it makes sense.

So, once you have completed the "reliability basics", the foundation steps of understanding criticality, failure mechanisms, availability and cost implications, where do you go from here to deploy a predictive maintenance strategy?

Step 1

Gain visibility of your data

The first step on the journey is to understand where you are at with your processes and equipment. The old maxim that ‘you cannot measure what you do not know’ has never been more apt. In a typical scenario, a company needs to understand what is the current performance of their assets. This may involve taking data that already exists at the plant level and visualizing that information to support useful decision making.

A company could marry this data with IT and maintenance management system level data to have a better view of maintenance histories paired with plant performance. In this situation, the key is often capturing data that has been previously lost and integrating it into the IT domain safely and securely where it can be manipulated, analyzed, and decisions can be made on that data.

Case study

OKEA contextualized data stream

The first building block for Norwegian oil and gas producer OKEA’s digital journey went live on the Draugen oil platform using ABB Ability™ EdgeInsight. This solution provides live streaming of contextualized data safely from the control system to the cloud with less than 1 second delay. OKEA can monitor their production through a cloud-based dashboard with real time production data and KPIs. The edge solution makes real time data easily accessible enabling operatives to access it anywhere, anytime. It also significantly reduces time to value for many and varied user cases including predictive maintenance.

ABB Ability™ EdgeInsight collects data from field devices, gateways and PLCs in Operational Technology (OT) systems. It then converts the various field protocols into one standard communication protocol and serves the standardized output to the IT infrastructure, while simultaneously guaranteeing no access to the field network, keeping the critical OT systems secure.

Step 2

Understand the gaps and remediate with added sensing

Once visibility has been established, the next step is to close any gaps where information could be lacking from critical assets in a plant. Here additional data points could be added to gain a deeper understanding of asset conditions. There is a vast array of sensors that can be deployed on electrical equipment, rotating equipment, and other plant assets that can then be part of a condition-based maintenance regime. This could be in the form of an engineered system tied into a control system or completely independent that allows informed decisions based on the condition of assets.

Many sensors can facilitate data gaps and remediation. The ABB Ability™ Smart Sensor converts traditional motors, pumps and mounted bearings into smart, wirelessly connected devices. It measures critical parameters from the surface of the equipment which can be used to gain meaningful information on the condition and performance of the machine, enabling users to identify inefficiencies within their system and to reduce risks related to operation and maintenance.

A condition monitoring system enables automatic, wireless monitoring of non-critical electric motors and rotating equipment. It can help detect machine vibration and temperature anomalies that could lead to equipment failure and production downtime. Information provided by the system can be accessed remotely by users. With wireless functionality, the system can easily be installed on existing infrastructures without requiring any extra shutdowns. Additionally, the engineering, planning, materials and installation costs are less than traditional wired solutions.

Condition and remote monitoring solutions are vital tools especially when assets are in remote and inhospitable locations, a common problem for the oil and gas industry.

Case study

Goliat

An example of the advantages of wireless monitoring for maintenance in the oil and gas sector comes at the Goliat field. This is an offshore oil field in the Norwegian sector of the Barents Sea located 85 kilometres northwest of Hammerfest. It has been developed using the world’s largest and most sophisticated cylindrical floating production and storage unit (FPSO) and built with the most advanced technologies to address the technical challenges of operating in an Arctic environment. With a capacity of a million barrels of oil, Goliat will also make minimal impact on the environment thanks to a land-based power supply and a zero-discharge operational concept, in part due to streamlined condition-based monitoring.

Part of advanced technologies is the wireless monitoring system across the rotating machinery fleet on Goliat from turbines to compressors and diesel driven generators. The scope of the condition monitoring system also extend across the electrical systems; from transformers, switchboards, drives, HVAC through to the subsea systems and cable. The complete marine systems critical to safe and reliable operation such as the offloading station, hull structure and cranes systems are monitored closely, equipment models monitor current performance against expected performance within parameters and indicate potential or actual deviation. Equipment faults, events and warnings are passed to the condition monitoring system and operators are notified of areas maintenance is recommended.

Step 3

Analyze and understand key trends toward faults

When it comes to accessing information from legacy equipment, edge devices once again play a crucial role. With a holistic data set, ABB Ability™ Genix APM Predict is a software solution to collect and analyze this data. Genix APM Predict gathers and presents real-time condition data from disparate systems into one dashboard so users can save time to action by having equipment health data and operational insights available all in one place.

It is an effective way to transition to a predictive maintenance strategy. It gives users who are both inside and outside the control room instant and secure access to the equipment data they need to make decisions that help optimize operations and reduce maintenance and operating costs.

Case study

BASF

Condition monitoring plays a vital part in German chemical company BASF’s drive to improve its maintenance operations. It has many non-critical low voltage motors and pumps that are inspected manually during routine maintenance. However, manually gathered information does not provide enough online information about the current state of degradation or about potential failures. Fleet management for rotating machines has been identified by BASF as a co-creation initiative which will help to further enhance overall plant availability, reliability and efficiency.

To overcome this, ABB provided an end-to-end solution that goes from wireless sensors up to advanced analytics and an enterprise dashboard for a fleet of rotating assets. The solution runs complex fleet diagnostic algorithms to improve the overall fleet operation. With this system BASF can easily gauge the status of each component in the plant using analytic algorithms running on ABB Ability™ systems. This in turn gives BASF enough information to monitor the equipment and to identify upcoming problems in the machine. This supports BASF operations to improve maintenance by detecting fault before failure, thereby offering an alternative solution to improve predictive maintenance.

Step 4

Leverage trends to predict faults before they happen and optimize maintenance strategy

Many approach predictive maintenance with a pure data science approach to predictive analytics. We believe using a combined approach of machine learning and model based analytics is more effective. In doing so we can compare actual performance against expected performance. We can compare plants across fleets and we can not only predict the probability of failure but also the time to failure. We can help carry out analysis to define the root cause and develop an appropriate action plan to revert.

Prescribe reliability with asset health

ABB Ability™ Genix APM uses this approach. It is a

software based on tried and tested models developed by experts that provides diagnostics

through predictive analytics to enable early detection of equipment problems. This enables the

operator to act long before faults or failure

occurs.

Data representing the plant in a healthy state is used to configure statistical models for equipment. The equipment covers components, units and systems as defined in the physical model. Heuristic knowledge (where available) is then used to complement the machine learning algorithms to provide the “best of both worlds.” This knowledge is expressed primarily in the Failure Mode and Effects Analysis (FMEA) format familiar to all reliability engineers.

The online system constantly checks the current plant state. These real-time signals can come from any source, typically from Distributed Control System (DCS), Condition Monitoring and other automated systems. The data is compared to the characterized models obtained during offline training and the user is presented with summary information in the form of Key Diagnostic Indicators (KDI) for each signal, KFI (Key Fault Indicators) for each failure mode and Key Performance Indicators (KPI) related to equipment efficiency. In addition to these indicators, the web-delivered user interface provides detailed analysis tools such as charts, summary statistical indices and future indicator prediction. Due to the generic nature of both the machine learning model and the FMEA heuristics, asset health may be applied across all sectors and many applications.

Case study

Enel Green Power

The work with Enel Green Power’s hydroelectric plants in Italy is a compelling example of delivering innovative predictive maintenance solutions that will lower maintenance costs and transform the performance, reliability and energy efficiency. The solution will enable a third of the units to move from hours-based maintenance to predictive and condition-based maintenance, leveraging ABB Ability™ Genix APM.

Collaborating closely since early 2018, the ABB and Enel have jointly developed and tested predictive maintenance and advanced solutions via a pilot on five Enel plants in Italy and Spain, including Presenzano, a 1,000-megawatt plant near Naples. The solution includes digital software solutions and services that will provide analysis of over 190,000 signals and the deployment of about 800 digital asset models, aimed at improving plant operational performance, reducing unplanned failures and enabling more efficient planned maintenance practices through predictive maintenance. The integration is expected to yield savings in fleet maintenance costs and increase plant productivity, with the added reliability expected to have a substantial impact on OPEX, with maintenance savings of between 10% across the fleet and 2% increased generation capacity

Step 5

Learn and adjust operations

Having reached this stage in the maintenance journey, the next step is to use key statistics to plan and expand across a fleet or enterprise, to gain real savings and improvements. Predictive analytics and asset performance mapping solutions have the capability to monitor, analyze, plan, and act for optimized management strategies.

These can link to other systems such as workforce management or overall enterprise management solutions. It is all about providing the right solution to a particular group of assets or problems that the customer is facing. ISO 55000 is a common international asset management system standard across the industries.

That is where we are at present, but it will not stop there. From here, the goal for maintenance strategies is to progress to a prescriptive maintenance regime. In this case like predictive maintenance, the basis is advanced analytics that will direct maintenance operations, but with the added benefit that it can act on the information rather than just advise. Rather than merely monitoring the sensor readings and saying that an asset is not performing optimally, it can raise works orders for a technician along with ordering any parts required for the operation.

Case study

PKOP

At the Kazakhstan PKOP Oil Refinery (Shymkent Oil Refinery) new capabilities realized from the implementation of Asset Performance Management programs will include criticality analysis, change management, and more robust reliability management with interconnection to an enterprise asset management (EAM) system. The digital plant platform, together with a professional consulting service will improve business processes related to critical equipment for operation and maintenance. Implementation of the project will reduce planned maintenance downtime from annually to once every three years.

Step 6

Establish a reliability culture

A vital component of a successful predictive maintenance strategy is having is a depth of experience in the sector coupled with plant operational, procedural and asset knowledge. ABB has decades of experience helping customers on a maintenance journey and while the individual solutions to those problems have changed, the core fundamentals of reliability engineering have not.

In order to attain the highest performance standards for reliability, companies must not neglect the vital role of people, no matter how advanced the technology deployed. A site needs to develop a reliability-centered culture where everybody recognises their personal responsibility just as the importance of safety is widely recognised.

A ‘reliability culture’ could be defined as a culture where everyone at all levels is continuously involved in the identification, understanding and application of appropriate reliability behaviors and practices, throughout an asset’s lifecycle.

People in all roles and at all levels work to improve the processes, systems and working relationships they depend on. High levels of equipment reliability is expected to result in improved safety, environmental and production benefits. A process of understanding the current state (assessment), establishing improvement teams, adding-checking-adapting process improvement streams, and competence development will ensure that reliability improvements are institutionalized and the benefits gained.

Reliability excellence is a journey, not a destination. Organizations who embrace this are better equipped to achieve lasting improvement in their operations and uptime. Business and technology are changing dynamically. How will you plot your path toward a predictive maintenance future?