Products

Power Generation Systems

China Unveils World’s Most Powerful Floating Wind Turbine Prototype

The world’s most powerful direct-drive floating offshore wind turbine, rated at 17 MW and co-developed by Dongfang Electric Corporation and China Huaneng, has been rolled out in China.

With the highest single-unit capacity and the largest rotor diameter globally, the milestone marks a new breakthrough in China’s offshore wind power equipment manufacturing and provides vital technological support for expanding into deep sea offshore wind development.

The turbine has a rotor diameter of 262 meters and a swept area of about 53,000 square meters, roughly equivalent to 7.5 standard football fields.

The hub height reaches approximately 152 meters, comparable to a 50-story residential building.

Compared to other floating offshore wind turbines, the unit features superior motion adaptability, capable of maintaining power generation even under greater platform tilts, with a time availability rate exceeding 99%.

It is also designed to withstand waves over 24 meters high and survive Category 17 super typhoons.

The unit is capable of generating 68 million kWh of clean electricity annually, enough to meet the annual electricity needs of approximately 40,000 households. Next steps include demonstration and validation deployment.

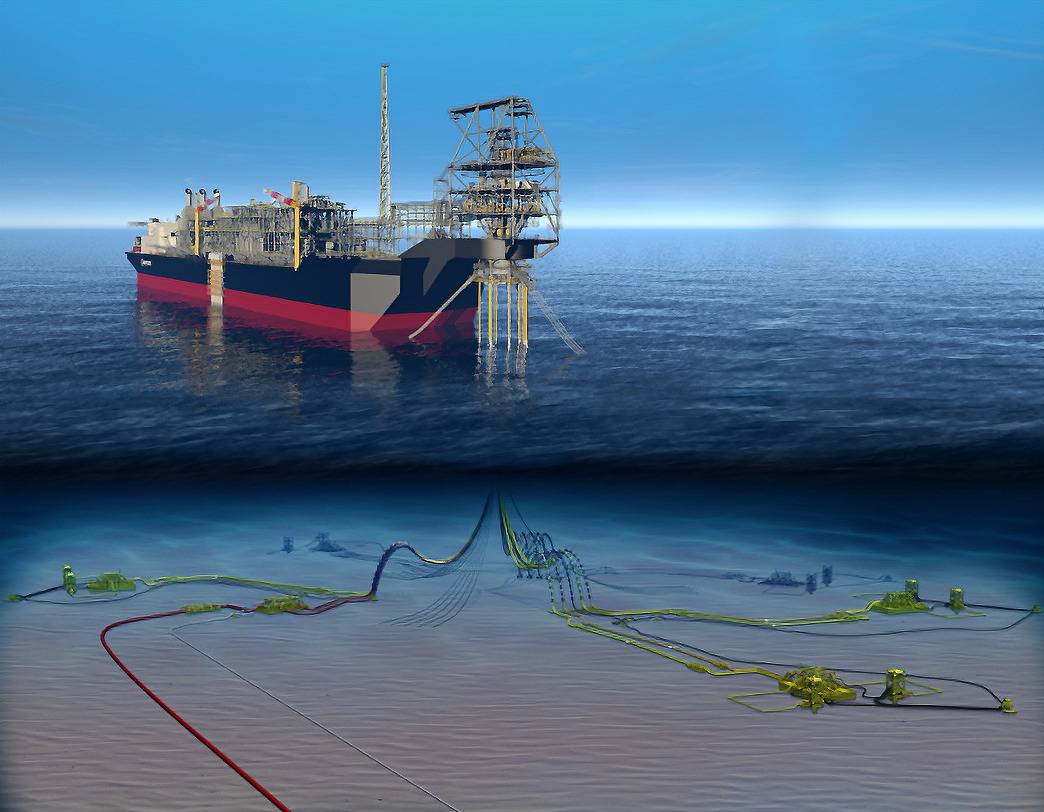

Offshore Fuel Cells to Cut Emissions from MODEC’s FPSOs

MODEC has entered into a contract with Eld Energy, a Norwegian fuel cell system company, to design and manufacture a solid oxide fuel cell (SOFC) system pilot unit intended for installation on one of the MODEC-operated floating production, storage and offloading (FPSO) units.

The SOFC development is one of MODEC’s critical decarbonization initiatives, which aims to demonstrate the viability of solid oxide fuel cells in offshore environments – offering a cleaner, more efficient alternative to traditional power sources.

The companies are currently in the second phase of collaboration, which includes engineering, manufacturing, installation, and offshore pilot testing of a 40 kW SOFC system.

The unit, to be manufactured by Eld Energy at its facility in Bergen, Norway, is scheduled for installation in 2026.

Eld Energy’s solution offers high-efficiency power generation with low emissions, aligning with the maritime and energy sectors' drive toward more sustainable operations.

By integrating advanced SOFC systems into offshore infrastructure, the companies aim to reduce environmental impact while maintaining operational reliability. The second phase pilot test represents the first real-world implementation of SOFC technology on an FPSO.

“Although we foresee technical hurdles to overcome in this R&D journey, we are committed to pioneering into it with a strong will to provide solutions that deliver stable energy with low GHG emissions,” said Koichi Matsumiya, Chief Technical Officer of MODEC.

Pushing the Limits: Subsea Compression Reaches New Depths at Offshore Field

Two SLB OneSubsea subsea compressor stations have been brought online at Shell’s Ormen Lange field, the second largest gas field in Norway, setting the record for the deepest installation of such systems ever.

The SLB OneSubsea subsea compressor stations, installed more than 900 meters below sea level in Norwegian Sea, represent the deepest subsea compression system ever deployed.

Gas is transmitted 120 kilometres to Shell’s Nyhamna processing plant onshore, also marking the longest subsea ‘step-out’ in history.

SLB OneSubsea’s award-winning subsea multiphase compressor is said to be the world’s first and only true subsea wet-gas compressor.

Conventional compressors require perfectly dry gas to operate safely and efficiently. The subsea compression system from OneSubsea, on the other hand, can operate with the unprocessed multiphase well stream, including condensates, produced water, and mono ethylene glycol (MEG), with liquid fractions ranging from 0% to 100%. It also tolerates sand and solids.

The Ormen Lange system uses two compression stations, each containing two compression modules. Each compressor can provide up to 50-bar differential pressure, configured in parallel for a large volumetric flow capacity.

The 32-MW subsea multiphase compression system will use onshore variable speed drives (VSDs) located 120 km away, eliminating subsea VSDs or topside alternatives to improve project economics.

Shell said the technology will unlock an additional 30 to 50 billion cubic meters of gas reserves from Ormen Lange as part of the project’s phase III, raising recovery to as much as 85% and providing increased supply to Europe.

Digitally Enabled Well Completions Tech from SLB Targets Production Boost

Global energy technology company SLB has launched Electris - a portfolio of digitally enabled electric well completions technologies that boost production and recovery while reducing the total cost of ownership of an asset.

Electris completions digitalize control of the entire productive area of the wellbore, providing real-time production intelligence across the reservoir.

This enables operators to predict, adapt and act with confidence in response to dynamic production conditions - improving reservoir management over the life of the well and accessing reserves that conventional systems leave behind.

There have been more than 100 installations of Electris completions technologies across five countries.

In Norway, Electris completions were deployed offshore to enhance oil production in an extended-reach well. The operator is using intelligence from the system to determine which zones are contributing to production to optimize oil output and minimize produced water.

Controlling water production with Electris completions has decreased the energy needed to lift and then pump treated water back into the reservoir, according to SLB.

Allseas Eyes Nuclear Power for Energy-Intensive Vessels

Dutch offshore contractor Allseas has made a pioneering step into the next generation of clean energy - developing an advanced nuclear power system tailored for energy-intensive offshore vessels and onshore industrial clusters.

Allseas has launched a five-year plan to design, develop and deploy a Small modular reactor (SMR), capable of delivering stable, high-density, zero-emissions energy in even the most remote, demanding environments.

Designed for marine propulsion and auxiliary power, the technology has potential for wider application – helping industrial clusters reduce reliance on fossil fuels, overcome grid congestion and secure a resilient, carbon-free electricity and heat supply.

The company has opted to explore High-temperature Gas-cooled Reactors (HTGRs) – a fourth-generation nuclear technology known for its inherent safety and exceptional reliability.

These compact reactors (25 MWe class) are powered by TRISO fuel particles, each no larger than a poppy seed. Each particle contains a uranium oxide core, coated with several advanced protective ceramic layers that securely contain fission products – even under extreme conditions.

Allseas’ five-year plan is already underway. In the first year, it plans to finalize initial design studies for offshore and onshore use.

This will be followed by prototype development and pre-licensing discussions in consultation with key stakeholders.

Consortium to Explore Floating Nuclear Plants for Ports, Islands and More

American Bureau of Shipping (ABS), CORE POWER and Athlos Energy have formed a consortium to evaluate the potential of positioning the floating nuclear power (FNPP) platforms to meet the energy demands of islands, ports and coastal communities in the Mediterranean Sea.

The group will research how FNPPs can potentially unlock a range of applications including the establishment of grid-scale electricity to remote locations, the delivery of emission-free energy to ports and the distribution of reliable clean energy to desalination plants that could provide potable water to drought-affected coastal communities.

According to ABS, the consortium will develop original FNPP concepts of operations (CONOPS) and publish a visual display of their prospective locations.

The ABS Global Ship Systems Center based in Athens will lead a Political, Economic, Social, Technological, Legal, and Environmental (PESTLE) study alongside key stakeholders with the aim of assessing the feasibility of adapting CONOPS to supply power and other benefits in the Aegean Sea.

“As global efforts accelerate to reduce emissions, improve energy efficiencies and strengthen energy security, the use of small modular reactors on floating platforms could offer a viable alternative. Floating nuclear power facilities show promise in supporting power grids, microgrids, industrial and port operations and data centers, among others,” said Christopher J. Wiernicki, ABS Chairman and CEO.