Products

Drilling Rig & Equipment Innovation

New Robotic Solution for FPSO Tank Cleaning

Ambipar and SBM Offshore announced a solution for cleaning cargo oil tanks on (FPSOs), a solution that importantly is geared to completely remove humans from entering tanks during cleaning activities.

Traditionally, cleaning these tanks involves significant health and safety risks for workers, who operate in restricted spaces under high temperatures and in contact with chemical residues. he new approach, resulting from collaboration between the two companies, will implement technology to use remotely operated robots to carry out the process in a safe way, dramatically reducing confined space risks and potential casualties.

The technology has already been successfully applied to an FPSO in offshore operation. The robot removed heavy oily sludge, while the onboard team (POB) monitored the process remotely, 24-hours a day, from a safe location outside the tank.

In addition to enhanced safety, the solution is said to reduce costs and timeframes involved in the cleaning process.

Kongsberg Maritime, Noble Corporation Join Forces for Offshore Drilling Innovation

Kongsberg Maritime and Noble Corporation have formed a strategic alliance for the co-development of advanced marine technologies for the offshore drilling sector. The companies signed a development program framework agreement, focused on the joint development, piloting, and commercialization of innovative solutions aimed at enhancing operational efficiency, risk assessment, and sustainability in offshore operations.

The first pilot project under this agreement will be launched later in 2025 on the drillship Noble Sam Croft, setting the stage for a series of collaborative development programs.

The agreement brings together Kongsberg Maritime’s marine technology portfolio with Noble’s deep operational expertise and modern fleet of 21 floaters. This synergy is expected to accelerate innovation cycles and deliver user-centric solutions that unlock new value for offshore operators.

“By working closely with forward-thinking companies like Noble, we can co-create technologies that not only improve performance and safety but also support the industry’s broader sustainability goals. Noble’s progressive approach and openness to innovation make them an ideal partner for this ambitious journey,” said Jouni Raatikainen, Executive Vice President Global Customer Support at Kongsberg Maritime.

COSLPioneer Semi-Sub Rig to Feature DualLink Digital Drill Pipe Tech

Well construction and production technology developer ReelWell, as part of strategic partnership with Odfjell Technology, secured multi-year contract with Vår Energi for the provision of DualLink-powered digital drill pipe technology.

As part of the agreement, Reelwell’s DualLink technology will be deployed offshore on the Norwegian Continental Shelf (NCS) for the first time.

The initial contract covers operations on the COSLPioneer rig for one year, with the option of four additional one-year extensions, with options to expand the scope for all Vår Energi installations across the North Sea.

The collaboration between Reelwell and Odfjell Technology aims to advance drilling efficiency and technology to meet the industry’s evolving needs.

Reelwell’s DualLink system integrates real-time telemetry with wellbore power, delivering enhanced operational control and ensuring uninterrupted power to downhole tools.

By directly powering tools in the Bottom Hole Assembly (BHA) that have traditionally been mechanically operated, the system eliminates the need for batteries and turbines, enabling instant surface control and enhanced functionality.

This advancement improves data transmission and ensures more precise, reliable operations throughout the drilling and wells process.

The combination of wellbore power and real-time telemetry allows Reelwell to oversee the collection and analysis of critical drilling data, facilitating continuous optimization of wellbore operations on the rig.

Odfjell Technology will be responsible for all the necessary drill pipe components and accessories for the project. In addition, they will oversee the many maintenance requirements, in support of Reelwell’s services and the COSLPioneer rig.

SLB’s OnWave Platform Set to Streamline and De-Risk Well Logging

Global energy technology company SLB has introduced the OnWave autonomous logging platform that enables more efficient and reliable acquisition of formation evaluation measurements in any well condition.

The first-of-its-kind technology autonomously acquires multiple, high-fidelity measurements downhole, without the need of a wireline unit, and wireline cable.

The OnWave platform’s cable-free design takes less than half the time to deploy compared with conventional wireline platforms, while enabling drill pipe rotation and mud circulation during logging operations, to enhance well safety and minimize stuck pipe events.

Deployable in any well trajectory, without the need for an onsite SLB crew, the OnWave platform executes tasks downhole that would typically be performed manually by engineers at surface, including borehole measurement acquisition and data quality checks.

It also verifies the tool’s position and functionality downhole through constant communication with surface, a capability most conventional cableless logging platforms don’t have. This assures confidence in the data acquisition quality and avoids remedial logging runs.

Deployed successfully across diverse basins, including in the United States and Middle East, the OnWave platform has demonstrated significant efficiency gains in complex well trajectories, SLB reported.

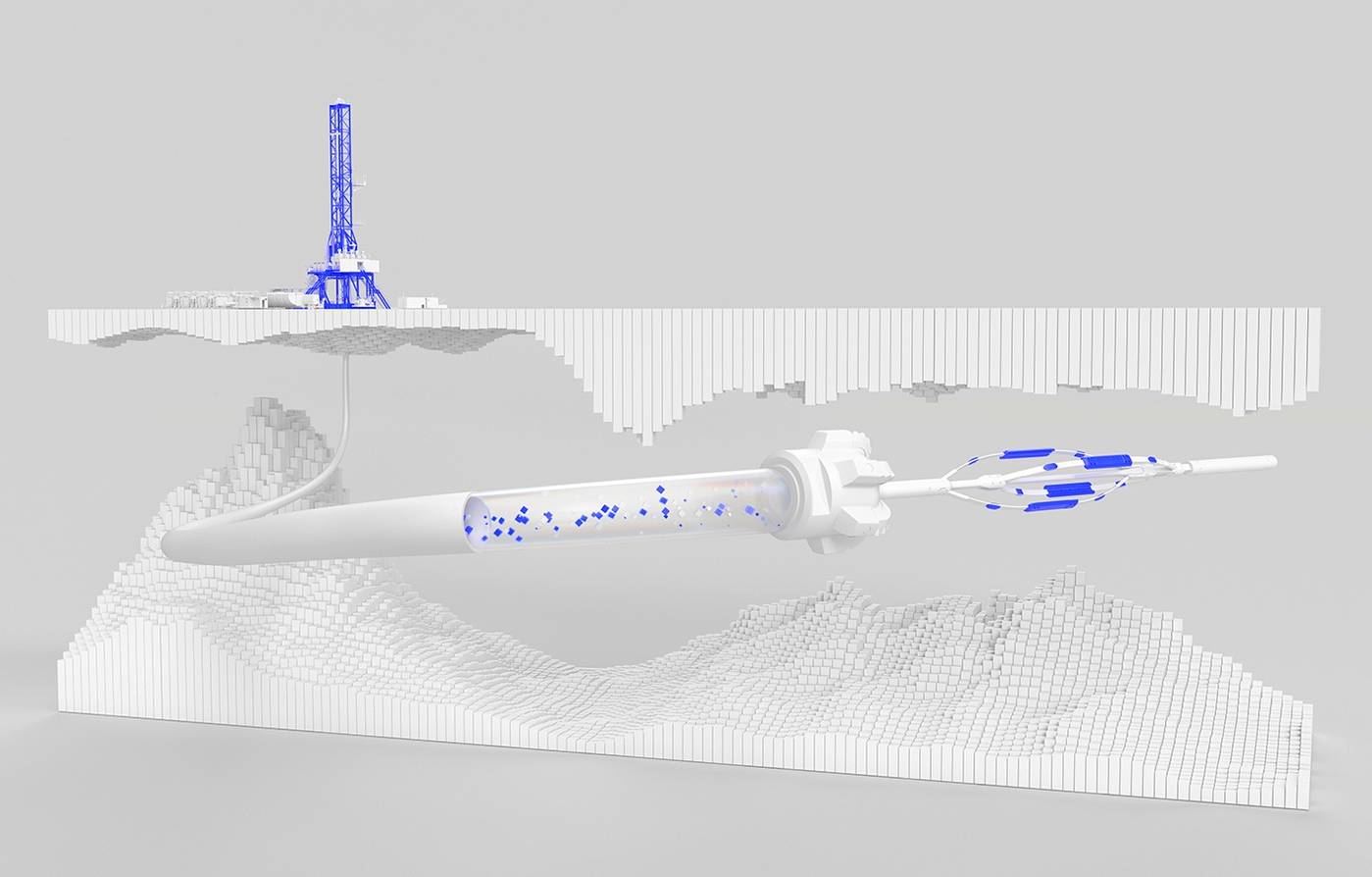

Halliburton’s LOGIX Automated Geosteering to Optimize Well Placement

Halliburton has launched LOGIX automated geosteering, a part of the LOGIX automation and remote operations family of solutions, that optimizes geological interpretation and well placement.

LOGIX automated geosteering redefines geosteering precision by combining automation, real-time intelligence, and advanced geological modeling to optimize well placement, maximize recovery, and improve operational efficiency.

The service optimizes well placement using real-time intelligence and advanced modeling to detect geological variations along the planned well path and updates it accordingly. Early detection reduces geological uncertainty and enables timely and accurate drilling decisions to keep the wellbore in target zones and maximize recovery.

Compatibility with LOGIX auto steer improves operational efficiency with a seamless transition between geological target changes and well path updates.

With real-time automation and intelligence, the system continuously projects ahead to detect geological variations, such as dips, and updates subsurface models.

The integration of LOGIX automated geosteering and LOGIX auto steer enables a smooth transition from well path updates to real-time drilling control to improve operational efficiency.

Expro Unveils Advanced BRUTE Tool for Deepwater Wells

Texas-based oilfield services provider Expro has launched its most advanced BRUTE high-pressure, high tensile packer system, designed to help operators work more efficiently in the extreme conditions of deepwater wells.

Engineered for the highest differential pressures in the market, this new technology gives operators the flexibility to set higher in the wellbore- saving rig time, reducing operational risk, and simplifying regulatory compliance.

As a recognized specialist in deepwater downhole solutions, Expro was commissioned by a super-major energy company for a high-spec 20k development in the Gulf of America. The inaugural use of the technology confirmed its pressure integrity and performance under extreme downhole conditions resulting in the release, and first successful deployment of the 12,850 psid-rated 12.25-inch BRUTE Armor Packer System in April 2025.

Building on the successful deployment of the 12.25-inch Packer System, Expro has also introduced a new 20/22-inch Packer System addressing historical challenges of retrievable mechanical packer systems, often constrained by internal diameter (ID) limitations, such as subsea high-pressure wellhead housings and supplemental casing adapters.

“The modular toolset provides unparalleled flexibility, making it the most adaptable solution on the market and positions Expro as the partner of choice for next-generation 20k deepwater developments,” said Jeremy Angelle, Vice President of Well Construction at Expro.