Power

Coupling Technologies

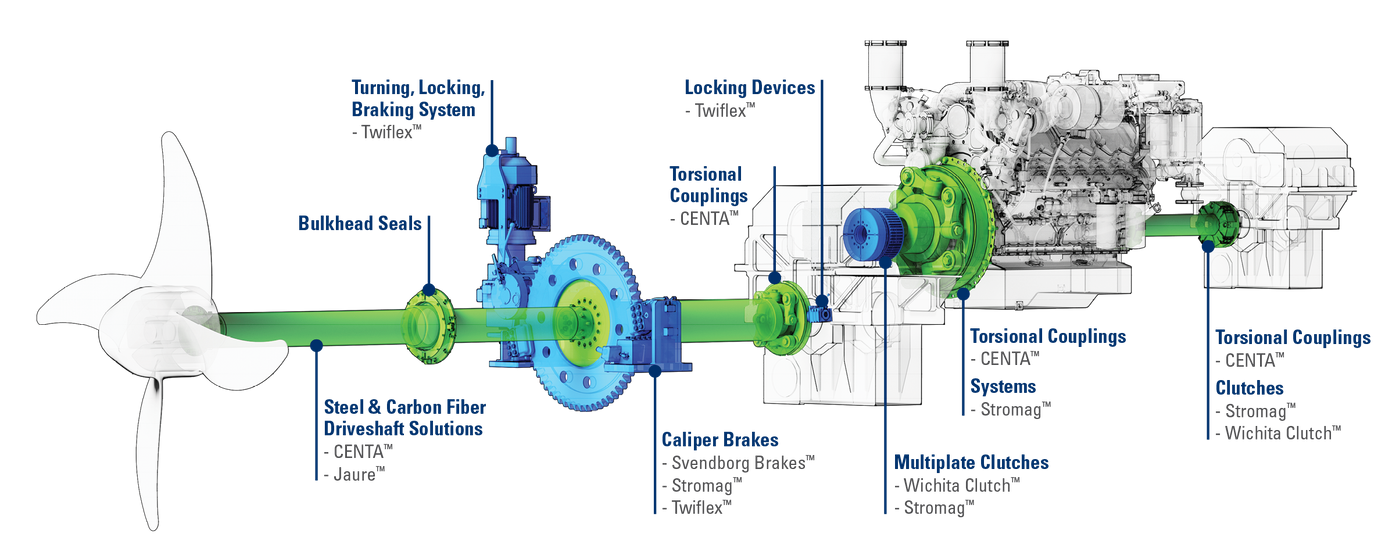

How Coupling Technologies are Optimizing Marine Power Transmission

By Bob Lennon, Marine Industry Manager, Regal Rexnord

CENTALINK Carbon Fiber Driveshafts are an ideal intermediate shafting solution for many different vessel designs. Highest operational misalignment, low weight, and noise reduction are key design features

Marine engineering is currently undergoing a transformation where efficiency, reliability, and sustainability are under a microscope — and companies are looking to find any and all operational improvements. Within this context, flexible couplings play a humble yet pivotal role in these advancements. Often-times overlooked, these components enable all types of marine power transmission by quietly absorbing shock loads, damping noise, compensating for misalignment and relative motions in the powertrain, and most critically, controlling harmful torsional vibration.

As vessels evolve to meet new environmental and operational demands, flexible coupling technologies are emerging as key enablers of performance and innovation.

Understanding the Role of a Flexible Coupling

In its basic function, flexible couplings connect a driver to a driven unit to transmit torque while accommodating misalignments; often they are also damping torsional and lateral vibrations and noise, while protecting other drivetrain components from potential shock loads.

These characteristics are especially apparent in marine-based applications where systems are subjected to fluctuating loads, variable speeds, and harsh environments daily. In these circumstances, the right coupling can mean the difference between smooth sailing and costly downtime of an expensive asset.

Common Types of Marine Couplings

Marine power transmission systems rely on a variety of flexible coupling styles designed to meet particular demands for varying operations. Metallic flexible coupling styles, like gear tooth and disc pack designs, are known for their high torque capacity and compact design. They are most often used in places where misalignment is minimal, and space may be limited (especially in diameter). A downside to gear tooth designs is that they do require periodic lubrication, where disc pack couplings are relatively maintenance free.

Elastomeric couplings, on the other hand, are better suited for higher misalignment operating conditions due to their ability to damp harmful lateral and torsional vibration from a system. They are generally low maintenance, requiring periodic inspection and planned replacement at their end-of-life expectancy (especially natural rubber-based designs). In some propulsion systems, intermediate shafting of either thin wall steel or filament-wound carbon fiber shafts are used to reduce weight and noise, while simplifying structural design complexity and cost.

With such a wide variety of flexible coupling styles available, selecting the right coupling is essential to ensure optimal system performance while ensuring long operating life and safe operation of the entire drivetrain.

Torsional Vibration and the Growing Concern in Modern Vessels

Torsional vibration is the angular acceleration and deceleration of a rotating shaft, superimposed to the steady-state rotation. This is heavily influenced by the interaction of the properties of the rotating connected masses; material stiffness, and the dynamic behavior of the entire powertrain. In marine settings, however, this phenomenon has become more pronounced with the shift from traditional low-speed internal combustion engines to medium and high-speed propulsion systems, hybrid propulsion systems, and even electric motor-based drivetrains.

With new regulations being introduced as the world trends toward sustainability, the push toward cleaner energy has introduced new sources of torsional vibration through more complex operating conditions of the drivetrain. High-pressure fuel injection methods, variation in cylinder combustion pressures from alternative fuel sources, and the integration of electric motors and generators all work to contribute to the growing complexity of the torsional dynamics of modern vessels.

Because of this, performing a detailed torsional vibration analysis (TVA) has become a critical step in the design of marine propulsion systems. A properly selected torsional coupling, confirmed by a careful TVA, can act as the well-tuned spring to help mitigate the harmful effects of torsional vibration while ensuring long-term system stability.

Designing for Efficiency and Reliability

Modern flexible coupling design is about more than simple torque transmission as engineers now consider a range of factors, including:

-

Torsional stiffness influence and damping characteristics

-

Thermal growth and alignment under loaded operation

-

Material selection for weight optimization

-

Integration with other drivetrain components, like shaft braking and locking, and condition monitoring systems

In many cases today, flexible couplings are part of a larger and more refined engineering solution that includes motors and engines, couplings and shafts, and clutches and brakes. When considering these factors into the design of a cohesive vessel propulsion system, these components can reduce the number of interfaces, minimize space requirements, and improve the overall efficiency of the drivetrain system.

Maintenance Best Practices

Despite their clear importance within the drivetrain, flexible couplings are frequently overlooked during routine planned maintenance. Improved system reliability, vessel uptime, and optimal life expectancy can be achieved by:

-

Performing periodic alignment checks on your drivetrain

-

Verifying that hardware is properly torqued

-

Scheduling inspections and maintenance in accordance with manufacturer’s recommendations

-

Documenting as-found conditions during routine inspections to trend wear and better prevent catastrophic failure

Regular inspection and alignment checks can significantly extend flexible coupling life expectancy and prevent unplanned downtime. In systems where torsional vibration is also a concern, onboard measurement tools and smart monitoring systems can provide real-time data to validate or refine TVA calculations and help you make proactive decisions to ensure the optimal operation and safety of your propulsion system.

The Future of Couplings and Marine Propulsion

With more regulations driving the evolution of the marine industry and the shift towards stricter emissions standards, digitalization, and the shift to alternative fuels, flexible couplings will continue to remain a critical component in drivetrain safety and reliability. Their ability to integrate with new technologies and incorporate new solutions into existing drivetrains positions them to be a cornerstone of modern marine engineering for years to come. Taking the time to ensure the proper flexible coupling is being installed and maintained, along with modern data monitoring solutions can effectively position your operation to push towards a more refined and sustainable future.

About the Author

Bob Lennon

Bob Lennon, Marine Industry Manager at Regal Rexnord, has more than 40 years of industry experience. He has expertise in flexible couplings, carbon fiber shafting, and torsional vibration.