Products

Safety Systems

Vissim’s Monitoring System to Enhance Safety of Qatar’s Offshore Assets

Norwegian technology company Vissim has signed a contract to deliver its Centralized Vessel Monitoring and Alerting System (CVMAS) to Qatar, designed to enhance safety and security for offshore assets.

CVMAS improves efficiency in vessel logistics and contributes towards reduced CO2 emissions and increased maritime situational awareness

The system will provide comprehensive monitoring and alerting capabilities, covering Qatar’s coastline and more than 300 offshore assets.

The core of Vissim’s technology is a specially designed software platform which, through input from millions of data points, provides situational awareness of the geographical area and increases understanding of maritime safety, security, and efficiency.

In Qatar, Vissim’s CVMAS integrates various data sources, including the automatic vessel identification system (AIS), weather data from platforms like Storm and Vaisala, and radar technology, to provide a detailed maritime overview.

Additionally, CVMAS integrates with maritime tools and platforms, including personnel and logistics management systems such as SkyTrac and DaWinci, and geographic mapping tools like ArcGIS. This integration also includes monitoring helicopter traffic and personnel onboard offshore assets, further enhancing operational safety and efficiency.

Vissim is delivering the system as a subcontractor to Qatar-based Bin Omran Trading & Telecommunications, which oversees local project management and offshore installation.

DMO Safety Tech to Continue Serving North Sea Oil and Gas Operator

Safety technology provider Dräger Marine & Offshore (DMO) will provide its portable gas detection and breathing apparatus systems to a major North Sea oil and gas operator as part of the long-term contract extension.

Due to run for five-years, with a further two one-year extension options, the extension of the existing supply contract means more than 10 U.K. North Sea assets will continue to benefit from Dräger’s portable gas detection and breathing apparatus systems.

Dräger offers a wide portfolio of respiratory protective equipment from light respiratory masks, powered-air purifying respirators and airline systems, to heavy respiratory protection, such as breathing apparatuses. For monitoring the respiratory protection of emergency and rescue teams, boards and telemetry systems are also made available.

As for the handheld gas detectors, the company’s portfolio includes single-gas and multi-gas detectors, gas detector tubes as well as calibration and bump testing equipment and software packages.

“Health and safety should be of the upmost importance to any business, whether that be in offshore oil and gas or otherwise, and by engaging DMO’s services for a minimum of five-years the operator is underscoring its long-term commitment to upholding the sector’s high standards,” said Lawrie Kerr, UK Sales Manager, Dräger Marine and Offshore.

Synaptec’s GreenLight Set to Tackle High-Voltage Cable Faults

Scottish firm Synaptec has launched Greenlight, a monitoring solution designed specifically to address high-voltage cable failures, stemming from faults in cable joints and terminations.

Greenlight provides continuous, automated visibility of all joints and terminations in a cable network, delivering early warnings of emerging faults before they become failures.

Designed for offshore wind farms and high-voltage power grids, it replaces manual inspection and reactive maintenance with a smarter, safer, and far more cost-effective approach to asset management.

The system is based on Synaptec’s patented Distributed Electrical Sensing (DES) technology, which uses fully passive sensors that require no power supply, no data networks, and no ongoing maintenance.

These sensors are easily retrofitted or embedded into cable joints and terminations at many locations over distances of up to 60 km from a substation.

Light from each sensor is sent via standard optical fibre to a central interrogator located at the substation. From there, Synaptec’s real-time analytics platform, Synthesis, processes the data, highlights anomalies, and delivers actionable insights through automated alerts and a visual dashboard.

With Greenlight in place, operators can identify and localize early signs of degradation, such as abnormal electrical currents, thermal stress, or evolving phase-to-screen ratios, at the exact location of the joint or termination at risk.

Rather than waiting for failure, maintenance teams can intervene precisely where needed and at the right time. Maintenance becomes targeted and efficient, and costly downtime is avoided.

The first commercial Greenlight installations have already been deployed with offshore wind operators and transmission systems internationally. There are plans for further large-scale installations throughout 2025.

Salunda’s Latch Monitoring Tool Bolster Safety of Pipe Handling on Drilling Rigs

Salunda, a provider of digitized solutions for safety critical industries, has launched the Latch Hawk 2 fingerboard latch monitoring device to improve safety during pipe handling on offshore drilling rigs.

Latch Hawk 2 provides a direct measurement of fingerboard latch status in real-time to prevent fingerboard DROPS incidents, eliminating the need for a spotter or camera.

Second generation improvements to the patented wireless monitoring device include new sensor technology with better shock and vibration resistance, a more robust design, cloud-based digital condition monitoring, and greater than seven-year battery life, which extends on the previous iteration by over two years.

The system integrates with all major OEM drilling control systems (including DrillView, Cyberbase, and Amphion) and can be installed using a patented ratcheting mechanism, adding an extra layer of protection against DROPS incidents for legacy fingerboards.

Improvement in the retrofittable design means there is no operational downtime during Latch Hawk 2 installation.

Latch Hawk works by using wireless sensors to determine the status of a latch. This data is then compared to the command status of the latch sent from the drilling control system. If an inconsistency is flagged by the system, an alert will be triggered within the control system HMI and a pipe racker interlock will be engaged preventing the chance of dropped pipe or other major failures. The system is IECEX, ATEX and INMETRO certified for use in Zone 2.

Latch Hawk is already deployed on dozens of rigs globally, with the new device now shipping as standard.

DrillDocs’ AI-Enabled Computer Vision Tech to Ensure Wellbore Stability

Digital shale shaker surveillance technology DrillDocs, together with Aker BP, has employed its AI-enabled computer vision technology to automatically detect cavings on the Norwegian continental shelf (NCS) for the first time.

DrillDocs’ CleanSight technology was deployed on the Noble Integrator rig while drilling in the Fenris field on the Norwegian Continental Shelf. At the time of the achievement, twelve sections had been monitored, totaling over 13,000 meters, including 16½-inch, 12¼-inch and 8½-inch sections.

The CleanSight system uses high-specification Axis Communications cameras designed for hazardous environments.

The technology features on-board processing capability for real-time image analysis. DrillDocs’ patented and proprietary image-processing algorithms continuously monitor material as it exits the rig’s shale shakers.

This capability allows the technology to calculate the amount, shape, and size of solids being recovered.

The data provided by CleanSight is said to enable better and faster decision making that can lead to enhanced drilling performance, borehole stability, and solids control operations.

Prior to the introduction of DrillDocs’ technology, shale shakers were only monitored on a periodic basis by drilling rig staff making visual inspections.

This meant that sporadic cavings, which offer an early warning of potential borehole instability, were frequently missed. By the time crews realized that the borehole was becoming unstable, the risk of a pack-off event - which often leads to the drill string becoming stuck in the hole - was already elevated.

The new approach allows the drilling crew to react in near-real-time to events happening in the wellbore, significantly reducing the risk of pack-off and the non-productive time and costs incurred when recovering from stuck pipe events.

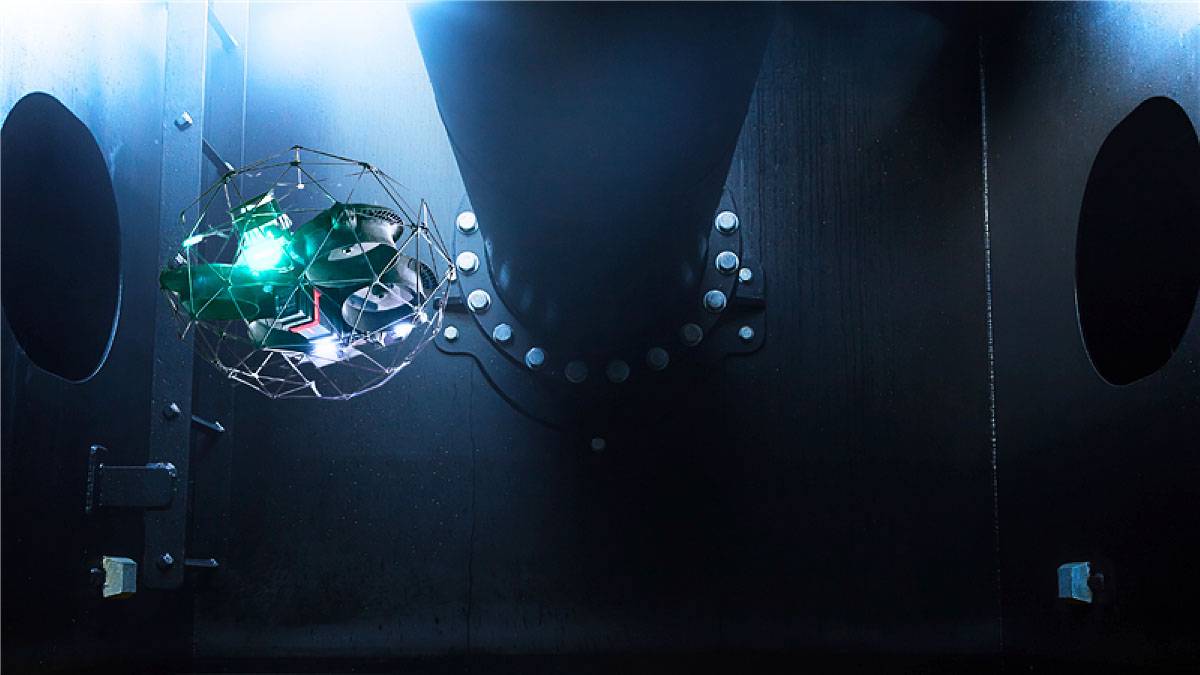

BV’s AI-powered Augmented Surveyor 3D

Bureau Veritas Marine & Offshore (BV) has introduced its latest digital innovation, the Augmented Surveyor 3D (AGS 3D), a cutting-edge inspection tool leveraging artificial intelligence and machine learning to detect and localize structural anomalies on ships and offshore assets.

The new solution was piloted successfully on a TotalEnergies-operated FPSO in West Africa. During the trial, drones captured extensive image and LiDAR data from two ballast tanks, which AGS 3D used to build a detailed 3D model, complete with AI-enhanced corrosion mapping. Following this success, TotalEnergies plans to extend AGS 3D to additional offshore assets.

AGS 3D streamlines inspection workflows by automating anomaly detection, defect localization, and corrosion analysis within a unified digital environment. By reducing human entry into confined spaces and expediting data processing, the solution improves both safety and efficiency across a range of marine sectors, including FPSOs, FSOs, floating wind platforms, and in-service ships.

The AGS 3D tool includes drone-based LiDAR scanning, AI-powered image analysis, automatic 3D defect localization, and a collaborative inspection platform—further enhancing the role of digital tools in maritime classification and survey activities.

Halliburton’s EcoStar Electric Safety Valve

Halliburton has launched the new EcoStar electric tubing-retrievable safety valve (eTRSV), a second-generation product that eliminates hydraulic actuation from safety valve systems.

The EcoStar eTRSV acts as a fail-safe that closes in case of well incidents at the surface to safeguard personnel and the environment.

Halliburton’s deep water DepthStar tubing-retrievable safety valve technology forms the foundation of the EcoStar eTRSV, which incorporates field-proven magnetic coupling technology and replaces the hydraulic actuation system with electric actuation.

This design increases reliability by isolating the actuation system from the completion tubing fluid and pressure.

It features independent and redundant electro-mechanical actuation and control systems, which enable more precise control, real-time position sensing, and valve health monitoring at the surface.

The innovation reduces the need for extensive surface facilities, streamlining operations, and enhancing personnel safety and field economics.

Viking’s Immersion Suit Designed for Women

Viking Life-Saving Equipment has launched the first Crew Transfer Vessel (CTV) immersion suit in the world designed for women working in offshore wind energy, using guidance on diversity and inclusivity from industry leaders Ørsted, Siemens and Vestas.

The VIKING YouSafe Cyclone suit joins a growing portfolio of VIKING PPE whose fit and features reflect the safety needs of female seafarers, pilots and technicians in the marine and offshore industries.

In UK waters, and elsewhere, getting the right PPE in place to best serve the safety needs of women offshore has become a focus for equity and inclusivity strategy at Ørsted, Siemens and Vestas.

Delivered in high-vis GORE-TEX NARVIK, the female-fit YouSafe Cyclone suit is approved to the same dual SOLAS/MED and CE/ISO standard as the male version and is available in multiple sizes.

Common features include compatibility with all standard offshore harnesses, durable Neoprene cuffs and neck seal, retro-reflective piping for increased visibility in dark surroundings, and a maintenance free zipper.

“Ørsted has identified female-specific PPE as part of the critical infrastructure we need for women to work safely offshore today and a necessity to attract more of them into this industry. We were delighted to work with VIKING as one of our key safety solution providers to take a significant step in the right direction,” said Lasse Hansen, Senior HSE Manager, PPE and TMSE, Ørsted.