Feature

Seabed Mining

The Nodule Collectors are Lining Up, Ready to Go

The battle lines have been drawn, and those on the “yes to seabed mining” side are getting ready to go.

By Wendy Laursen, Marine Technology Reporter

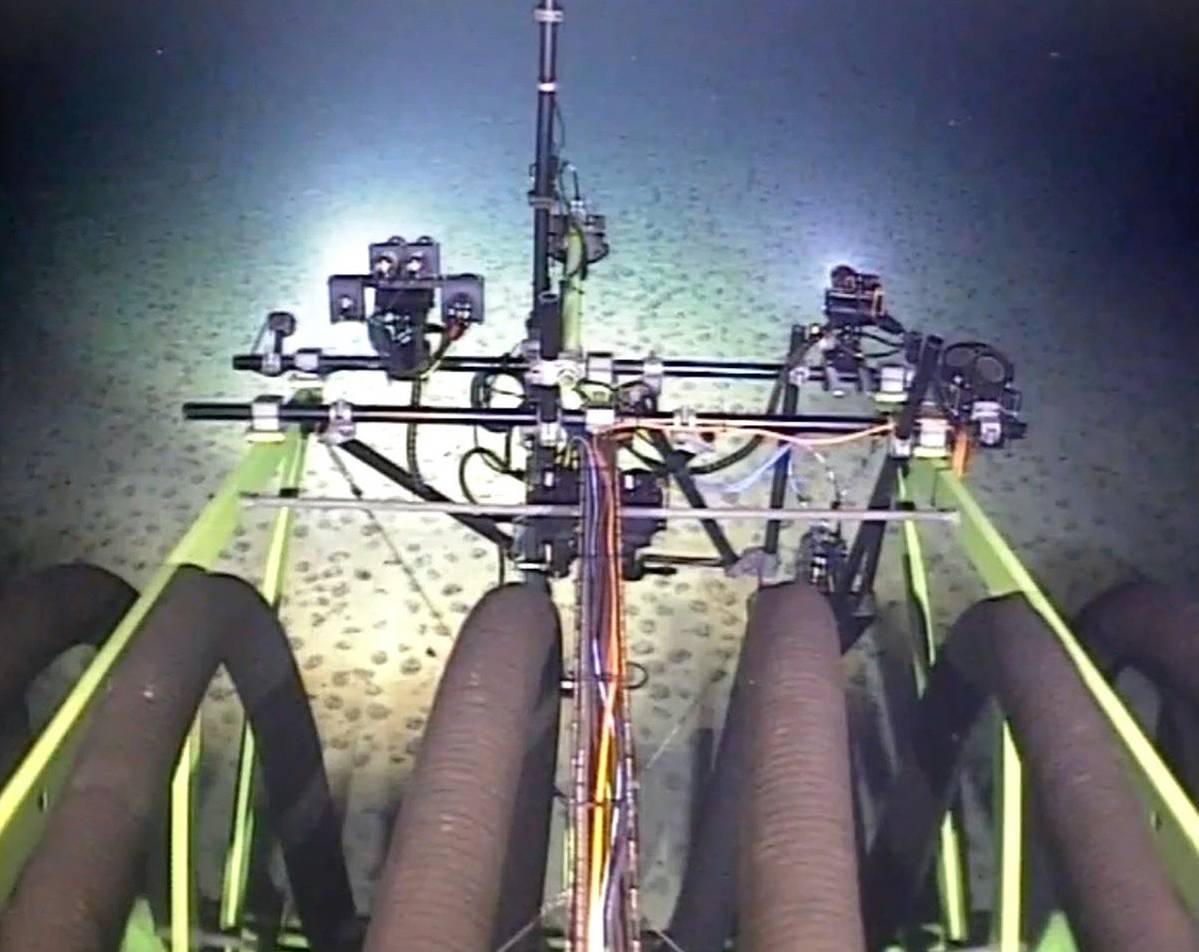

Engineers prepare to launch the pilot collector vehicle to the seafloor

Image courtesy of TMC.In January, Norway said “yes” to seabed mining, adding its weight to the momentum that is likely to override the calls for a moratorium by over 20 countries and companies such as Google, BMW, Volvo and Samsung.

Those against mining aim to protect the unique and largely unknown ecology of the seafloor from physical destruction, sediment smothering and noise pollution.

However, the International Seabed Authority (ISA) has granted 31 exploration contracts in international waters and is expected to confirm mining guidelines this July, or perhaps next. Nearly two thirds of the licenses are for nodule mining, the most advanced sector.

Belgium-based GSR, part of the DEME Group, has Transocean as a cornerstone investor, and it conducted trials of a patented nodule collector, Patania II, at 4,500 meters in the Clarion Clipperton Zone in 2021. Full-scale trials will be conducted in 2027.

Patania II uses jet water pumps to lift nodules into a collection drum. Peer-reviewed research has indicated that released sediment-laden water led to a low-lying, laterally spreading turbidity current. Only 2-8% of the sediment mass was detected 2m or higher above the seabed and hadn’t settled after several hours.

“All indications to date point to polymetallic nodules having the potential to become one of the most responsible ways to help meet the world’s spiraling demand for metals,” says GSR managing director Kris Van Nijen. “Our focus is on developing a source of high grade, low carbon minerals which can work alongside other strategies to reach the eventual goal of a circular economy and a stable planet.”

Canada-based The Metals Company has partnered with Allseas which has a converted drillship, Hidden Gem, set up for nodule collection.

Onboard technology developments include the vessel’s launch and recovery system (LARS) which deploys and recovers the collector and feeds its power and control umbilical. It has passive heave compensation which nullifies the wave, current and vessel motions that influence loads in the power umbilical. The LARS can operate in up to 3.5m wave height significant. The physical connection and disconnection between collector and power umbilical is performed subsea, and the LARS is fitted with a routing system that keeps the umbilical in a single plane during collector operations.

The collector’s front-mounted Coandã-effect nozzles guide water over the seabed, creating negative pressure and a suction effect that picks up nodules. A diffuser at the rear creates an exit from where the sediment flows out, over 90% of which stays close to the seabed. The collector is fitted with low-impact tracks, and to further limit sediment disturbance, it has a fines rejection system.

This type of technology was first tested successfully in the 1970s by major Western corporations like Shell, BP and Kennecott. “The focus since then has been on scaling while ensuring the lightest environmental impact,” says The Metals Company CEO Gerard Barron. In-field collection system trials conducted in 2022, where TMC collected 3,000 tonnes of nodules, have helped further advance the design.

Digital twin technology analyzes data gathered from multiple sensors and assets to enable 3D visualization of operations in real time. AI modelling can then determine the environmental impacts of the operation and test how, for example, how increasing production rate or collector speed would affect sediment mobilization and enable TMC to model different scenarios to reduce this impact, says Dr Greg Stone, Chief Ocean Scientist.

Research conducted by Nauru Ocean Resources, a subsidiary of The Metals Company, found that organisms continue to be present and alive 12 months after having been influenced by a seafloor plume from its pilot collection system test.

The Metals Company recently signed a binding MoU with Pacific Metals Corporation of Japan for a feasibility study on processing 1.3 million tonnes of wet nodules per year, and the company is also exploring opportunities for the construction of a U.S. refinery - the Pentagon is expected to deliver an action plan on nodules by March 2024.

UK-based Soil Machine Dynamics (SMD) designed, developed and delivered the mining machinery planned for the Solwara 1 Seafloor Massive Sulphides project some 15 years ago, and it is now developing a patent pending, least impact, nodule collection system that utilizes mechanical and hydraulic technology.

The company’s SMD Q-Collector range is available in a variety of sizes to suit vessel and client requirements. Engineered to have a low submerged weight, these vehicles are made with light plastic tracks and buoyant syntactic foam. The collection vehicle uses sonar to identify the position of the nodules and has attained collection efficiency rates of at least 97% in recent university trials.

Ian Maskell, principal engineer, says: “The eyes of the world will be on these projects, and this will be the most regulated industry in the world.” However, commercial success depends on many factors, not least a predictable OPEX. Over the past four years, SMD has worked with Oil States Industries to calculate cost per tonne figures for prospective customers.

Oil States’ Merlin™ riser systems were successfully deployed on both the TMC / Allseas and JAMSTEC 2022 pilot projects. They also hold a world record water depth for a producing riser system of 14,764 feet.

Impossible Metals is developing a nodule collector which, unlike other technologies, is untethered and hovers above the seabed, picking nodules with robotic arms. CEO Oliver Gunasekara cites three unique developments: the battery-operated buoyancy engine, fast-acting robotic arms and the AI algorithms that guide them, identifying and avoiding nodules with visible life present.

A second-generation collector, Eureka II, is currently being tested off the US east coast. It has three arms, but the much larger Eureka III will have 16 arms. Gunasekara estimates that a fleet of around 16 of these autonomous collectors would be a break-even point for commercial operations, with scale up from there possible gradually.

Hundreds of collectors can be deployed concurrently. Once a collector has achieved its 6,000kg payload, it can return to the surface, and as the surface vessel reaches capacity, it can return to shore while the collectors continue to load on a second vessel.

There is no sediment release mid-water like the other technologies and no noise from pumps or the DP system of vessels. “We have really gone out of our way to mitigate all of the negative feedback that the industry has received.”

Still, the pushback continues. A 2023 Planet Tracker report highlighted that, like crude oil, nodules take millions of years to form, so biodiversity loss would essentially be permanent. And in February 2024, the European Parliament passed a resolution raising concerns about Norway’s mining intentions.