FEATURE

OFFSHORE WIND

Floating Offshore Wind: Opportunities & Challenges

The floating offshore wind industry, still considered nascent - and minuscule compared to the installed capacity of its "older brother, "- that is the conventional, fixed bottom offshore wind industry (29GW at 2019 end) - is showing promise and is expected to take off big time by the end of the decade.

While the current installed capacity – less than 100MW - is small and focused on pilot and demonstration projects, the potential is there for the floating wind farms to reach and, theoretically, even surpass the installed capacity of the traditional offshore wind turbines, and not by a little, given that there are no water depth limitations for installation.

Offshore Engineer’s Greg Trauthwein interviewed Philip Lewis, Director of Research, World Energy Reports, and author of OUTLOOK FOR OFFSHORE WIND POWER, THE FRONTIER OF FUTURE ENERGY, to learn more about the opportunities and challenges in the industry that could rise to prominence sooner that one might think.

Lewis first provided some context on the traditional offshore wind industry, which uses fixed-bottom turbines, installed at water depths of up to 60 meters.

"…bottom-fixed offshore wind farms have been in operation since 1991, and so this is not a new industry. We saw the true industrialization of the sector over the last decade and the adoption by more and more European and East Asian countries of this increasingly cost-competitive technology," he said.

80% of wind resource found in deeper waters

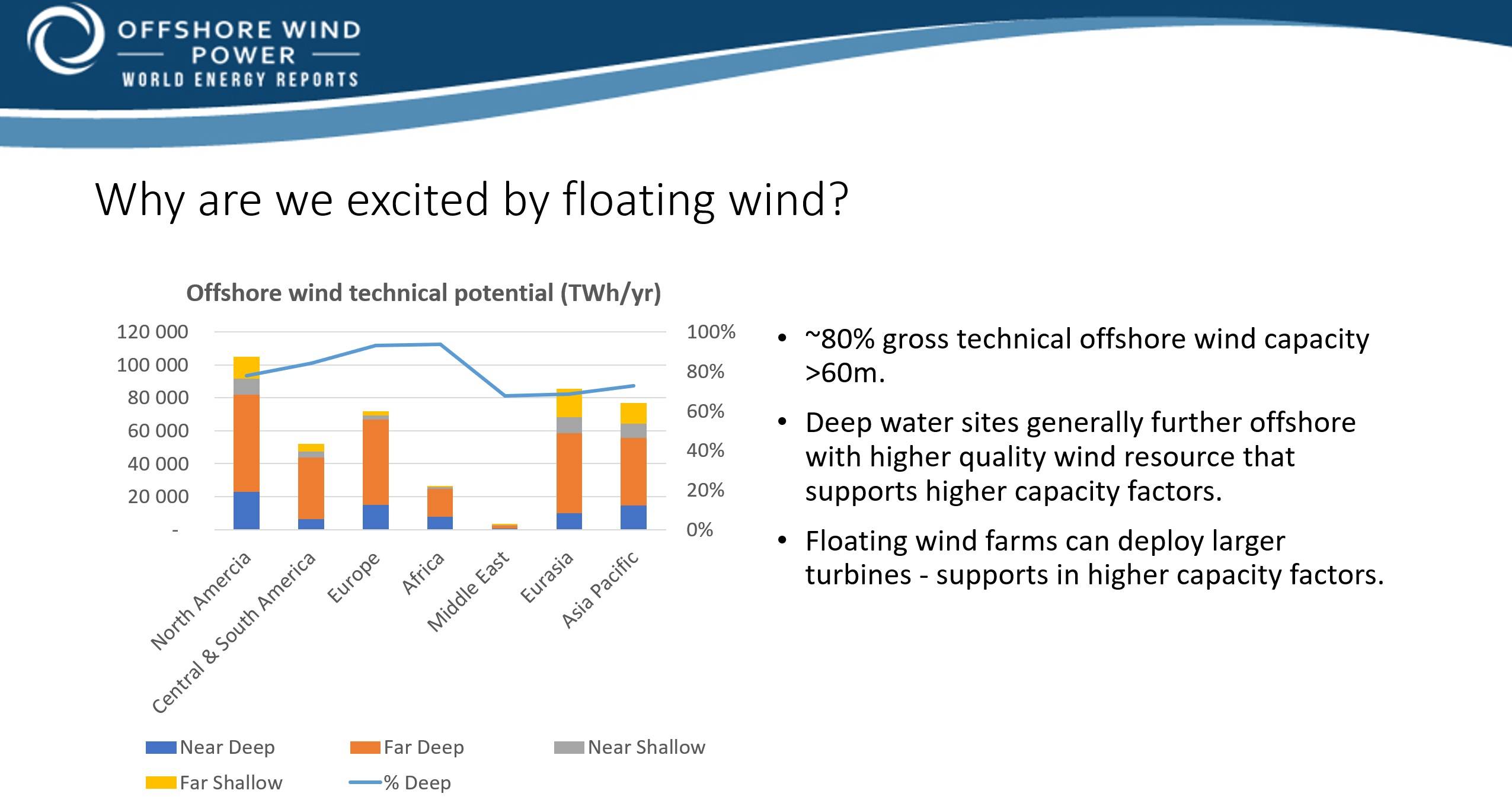

However, Lewis says the reason World Energy Reports is so interested in floating offshore wind is the sheer amount of resource available beyond the 60-meter water depth, the general threshold considered for floating solutions.

"Some 80% of the world's wind resource is found in deeper waters suited to floating wind foundations. These resources are generally able to access higher quality wind resource. Further, floating structures can deploy larger turbines which support higher capacity factors, which means they produce more electricity," Lewis says.

So, where are we now? We are passing from the prototype and demonstration project phase towards industrial-scale floating wind farms, Lewis says.

According to World Energy Reports, the floating wind installed capacity will reach between 8 to 10 GW by the end of this decade, and next decade WER expects to see more than 60GW of floating wind farms commissioned.

Worth reminding, DNV GL recently said that floating wind could grow 2000-fold, by 2050 (DNV-GL), from 100 MW today to 250 GW in 2050.

Big opportunity for offshore O&G supply chain firms

Lewis says that the expected growth in the floating wind industry also represents a significant opportunity to those in the supply chain, and the companies that have traditionally served the offshore oil and gas industry. Concrete contractors will benefit, as well.

According to WER's offshore wind report, floating offshore projects differ from bottom fixed in that offshore construction and installation calls on methods very familiar to oil & gas offshore yards and offshore support vessel (OSV) owners and operators.

"At World Energy Reports, we see the opportunities for traditional offshore and marine companies that support the oil and gas sector like offshore yards, mooring system chain and anchor manufacturing and OSV operators. We also see exciting opportunities for those not traditionally involved in the offshore oil and gas market, such a pre-cast concrete and in-situ concrete contractors and manufacturers of synthetic ropes," Lewis says, however warning that WER does not feel that the supply chain has fully embraced the scope and scale of the opportunities that exist in this sector.

60 concepts

World Energy Reports is tracking some 60 floating wind substructure concepts. Of these 60, 38 have been tank tested and 20 scale tested in the field and 3 concepts have been demonstrated at full scale.

"Only 2 concepts have reached the stage of pilot array to date, although several more concepts will reach this stage over the next couple of years. We expect to see the first pre-commercial arrays - that's under 100MW by 2022 - and the first commercial arrays over 100MW by the middle of the decade," Lewis says.

Challenges

With any opportunities, invariably, there are challenges. What has been touted as a benefit earlier in the article – bigger size – can also pose a challenge.

"Firstly, I think most people would struggle to picture how big these units can be. If we take an industrial-scale floating wind farm, you could easily expect to see 50 to 100 steel or concrete or substructures to meet a 200-300 day installation weather window.

Taking the example of a steel floater, Lewis explains, that could be 150,000 to 350,000 tonnes of steel to be produced in two to three years, with each 2500-3500 tonnes structure requiring some 6,000+sqm of area.

"The structures are physically large and will be required in large quantities," Lewis says.

Furthermore, in addition to waterside laydown areas, there will be a need for assembly berths and wet storage, where turbine diameters exceed 200 meters.

Lewis' World Energy Reports also sees a major opportunity, as well as a constraint, in the quantity and capacity of anchor handlers and construction vessels to tow wind turbines, pre-lay moorings, and hook-up systems.

“There is a specific challenge to adapt offshore oil & gas mooring solutions to floating wind – addressing weight, quantity, and footprint of the anchors and mooring lines,” Lewis explains.

Dynamic array and high voltage export cable manufacturing and installation capacity is another challenge to address, especially the manufacture of above 66kV dynamic export cables, he says.

And finally, Lewis says, the inspection of large numbers of in-water components and where the question of in-situ (floating-to-floating) versus tow-to-port repair and maintenance programs is to be addressed.

“SOME 80% OF THE WORLD’S WIND RESOURCE IS FOUND IN DEEPER WATERS SUITED TO FLOATING WIND FOUNDATIONS. THESE RESOURCES ARE GENERALLY ABLE TO ACCESS HIGHER QUALITY WIND RESOURCE. FURTHER, FLOATING STRUCTURES CAN DEPLOY LARGER TURBINES WHICH SUPPORT HIGHER CAPACITY FACTORS, WHICH MEANS THEY PRODUCE MORE ELECTRICITY.”PHILIP LEWIS

DIRECTOR OF RESEARCH, WORLD ENERGY REPORTS