Software Solutions

TrueProp

TrueProp’s Digital Shift

Propeller Inspection Technology Helps Rewrite Shipyard Economics

The importance of the propeller to the vessel’s drive train cannot be understated. If propeller geometry is out of whack, either from inaccurate design or a strike in the water, the results, if left unchecked, can resonate through and negatively impact the entire propulsion and ship system. Adam Kaplan, CTO, TrueProp Software, discusses how this company, started in 2021, uses 3D scanning and proprietary software to help extract time, money and guesswork from the propeller repair operations, helping both the boat yard and the boat owner not only save time and money, but to receive a properly repaired propeller with the digital documentation to back it up.

By Greg Trauthwein

In the world of shipbuilding, the propeller is both an engineering marvel and a potential bottleneck. A single mismatch in blade pitch can translate into fuel inefficiency, vibrations, warranty disputes and costly delays. Traditionally, ensuring that a propeller meets exacting standards has been a labor-intensive and time-consuming process, one that often required shipping the unit off-site for inspection and repair, tying up resources and schedules.

But in less than a decade, TrueProp Software, founded by mechanical engineer Adam Kaplan and business partner Jill Aaron, has transformed propeller measurement from a mechanical, probe-based chore into a high-speed, non-contact, data-driven process. For shipyards, this evolution has the potential to save weeks of schedule time, cut labor and outsourcing costs dramatically, and provide a level of quality documentation that was previously impractical.

There's some huge advantages to being able to go into a dry dock and inspect the propeller. Normally they would have to take that propeller off. That's a day of work, load it up on a truck, send it to a specialist, get it back a week later, mount it back on the ship. Well now we can just do a lot of that process right in-house in the dry dock. You look at how things were done traditionally, and you just see that there's kind of this big opportunity where there's a lot of costs and a lot of people with their hands in it from the dry dock to the riggers to specialists. If you can pull that in-house and have one or two guys who are able to just 3D scan the prop, it pays for itself usually in one or two jobs.”

- Adam Kaplan,

CTO, TrueProp Software, LLC

From Academic Curiosity to Industry Tool

Kaplan’s journey toward digitizing propeller inspection began at the University of New Hampshire, where he was experimenting with digital image correlation, a stereo camera technique that produces 3D models of surfaces without physical contact. The early equipment was prohibitively expensive for field use, but it planted the seed: if the technology could be made portable and affordable, shipyards could capture precise propeller geometry on site, avoiding costly disassembly and transport.

That vision gained traction in 2016, when Kaplan and Aaron spun off TrueProp Software from HydroComp Inc. The company initially focused on modernizing existing inspection machines, many dating back to the mid-20th century, by adding digital sensors and interfaces. The next leap came in 2017 with TrueProp Virtual, a software platform that could process 3D scan data from portable laser and structured-light scanners.

The breakthrough for shipyards was mobility: instead of bringing the propeller to the inspection tool, TrueProp allowed the tool to come to the propeller, even in dry dock.

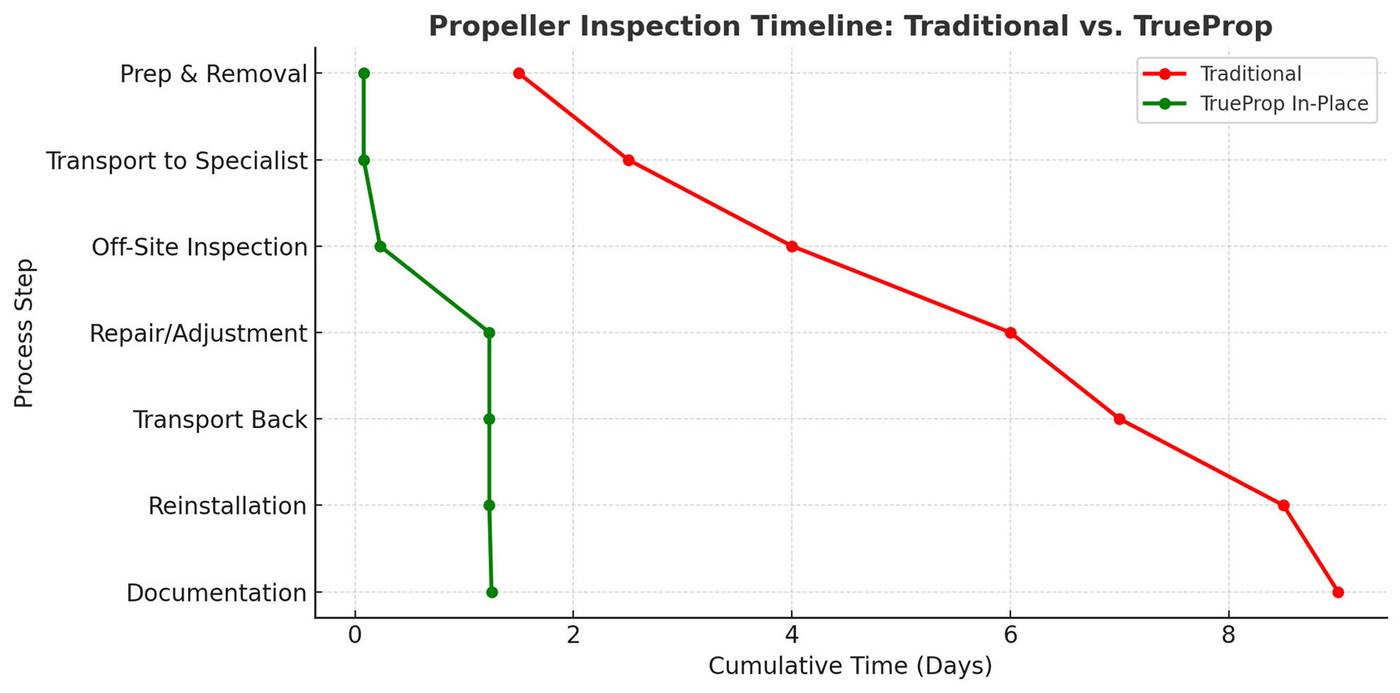

Time is Money

Shipbuilding margins are tight, schedules are unforgiving, and customers expect documentation that proves quality. In this context, the benefits of TrueProp’s approach can be distilled into three critical categories:

-

Time Savings

-

Traditional method: Remove the propeller, transport to a specialist, inspect, repair, transport back, re-install—often a 10-day process.

-

TrueProp method: Scan in situ, generate a full 3D condition report in hours, and decide immediately whether off-site work is required.

-

Result: Potentially eliminate a week or more from the build schedule.

-

-

Cost Reduction

By avoiding removal and transport for undamaged props, shipyards save on rigging, trucking, and reinstallation labor. Even when repairs are needed, pre-inspection data ensures specialists arrive prepared, cutting repeat visits. “It pays for itself in one or two jobs,” Kaplan says of the TrueProp package.

-

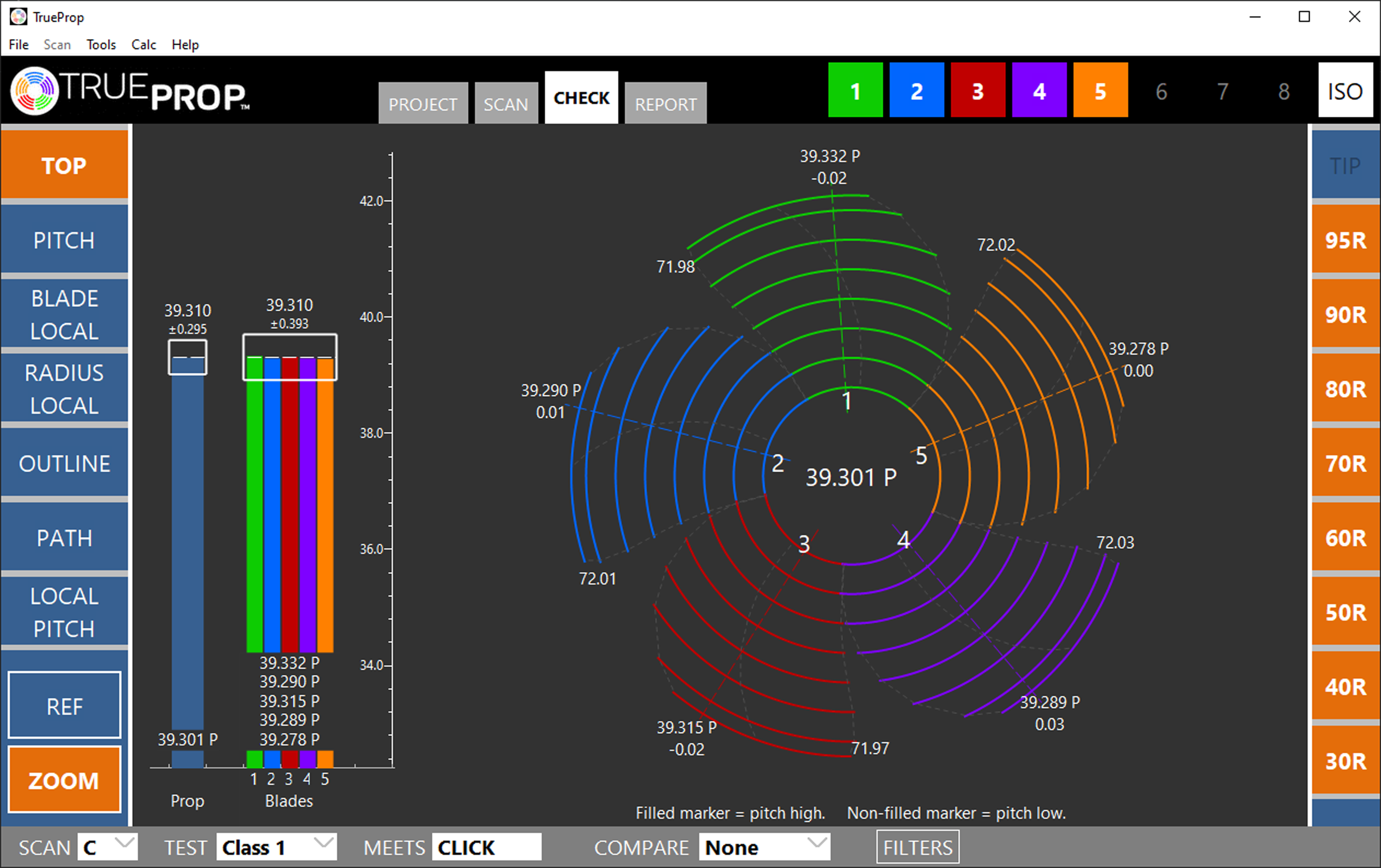

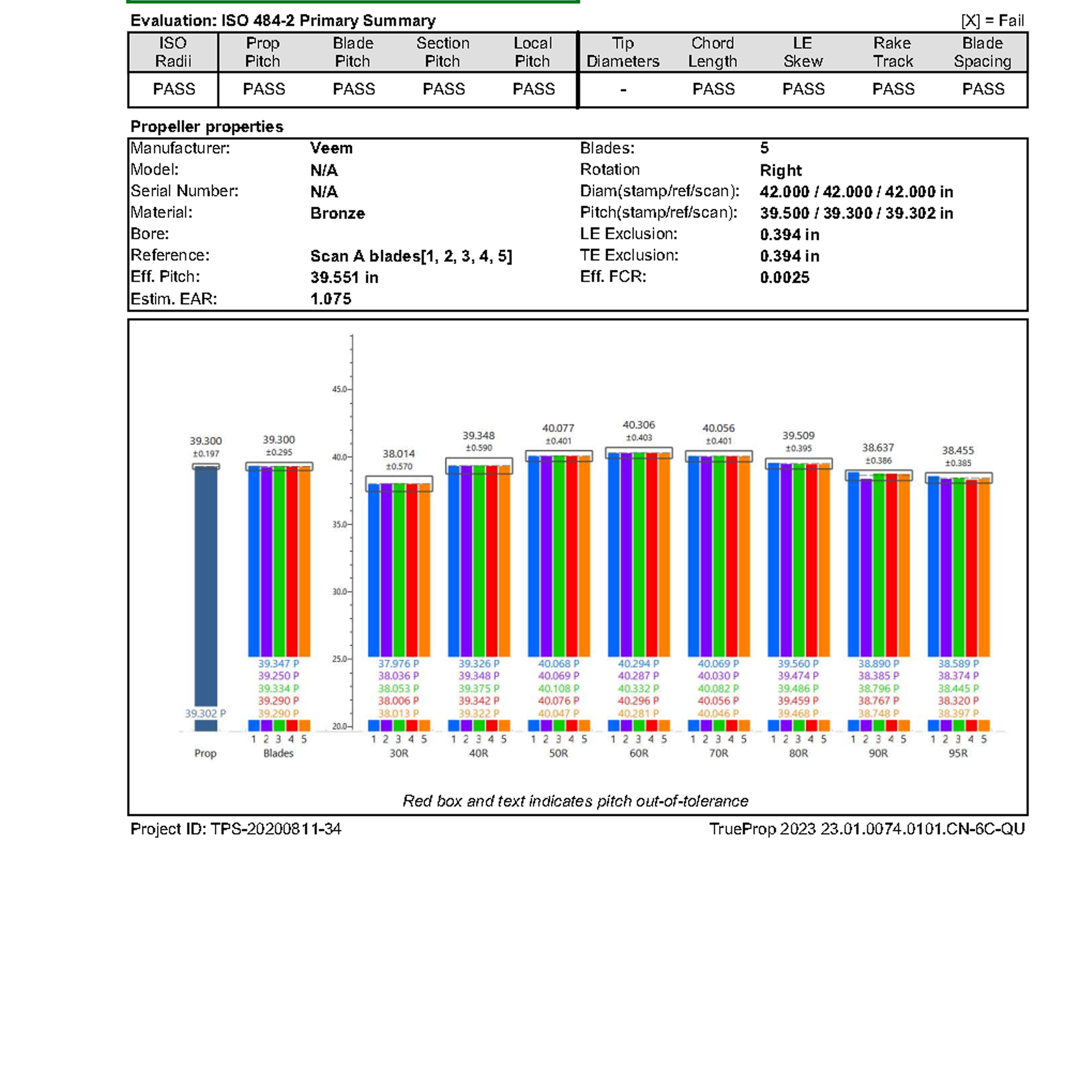

Quality and Documentation

Scans produce precise, repeatable measurements of every blade. Reports mirror the “before and after” alignment printouts familiar in the automotive world—providing shipowners proof of work and a digital record for future reference. Digital archives support warranty claims, accident investigations, and future replacements.

How It Works

At its core, TrueProp is measurement software. In the traditional configuration, it connects to mechanical “drop rod” pitchometers, devices that measure blade radius, drop, and angle at set positions. With TrueProp Virtual, the data source shifts to 3D scanners. Kaplan’s team has curated scanner packages optimized for maritime conditions:

-

HX2 for entry-level use, suitable for props up to 80 inches.

-

FreeScan Combo for higher speed and larger props, up to ~160 inches.

-

FreeScan Nova Trak, a tripod-tracked hybrid system capable of scanning both propellers and large hull components.

Portability is key. The FreeScan Combo, for example, fits in a small carry-on case, ready to fly to any shipyard or dry dock. All that’s required on-site is a power source and physical access to the propeller.

Impact on the Build Process

For newbuilds, TrueProp offers a way to verify propeller geometry before installation and during sea trials. If the vessel fails to reach design RPM, the propeller’s pitch can be adjusted to match the real-world load.

“Think of it like an airplane wing,” Kaplan explains. “If one blade is at a slightly different angle than the others, you get uneven loading and pressure pulses that cause vibration. Matching all blades as closely as possible maximizes efficiency and smoothness.”

In the past, making such adjustments might mean pulling the propeller out of service for days. Now, shipbuilders can measure, diagnose, and in some cases correct pitch right in the dry dock, keeping the delivery schedule intact.

Case Study: Lessons from a Museum Submarine

One of TrueProp’s more unique demonstrations came not from a commercial shipyard, but from a naval museum in Portsmouth, NH. The USS Albacore, a pioneering teardrop-hull submarine from the 1950s, sits on display with its original propeller.

Kaplan’s team scanned the 15-ft.-diameter prop in direct sunlight, using only a ladder, battery packs, and a laptop. The process took two hours. The scan revealed a subtle bend on one blade, a bend likely caused during transport or installation as a display.

For Kaplan, the project underscored two points that apply directly to shipyards:

-

Even careful handling can introduce damage.

-

On-site scanning is both practical and revealing, even in challenging environments.

Quality Assurance for the Shipowner

While shipbuilders see the internal efficiencies, the end customer experiences TrueProp’s value in a different way, through the assurance of documented quality.

Kaplan likens the final report to an automotive alignment sheet:

-

Before: Numeric tolerances show where the propeller was out of spec.

-

After: Green indicators across all blades confirm that repairs or adjustments brought it into compliance.

This transparency builds trust, provides a baseline for future maintenance, and strengthens the shipbuilder’s reputation for delivering high-performance vessels.

Implementation and Training

Adopting TrueProp is a low-friction process. New customers typically receive a live demonstration and Q&A session; four hours of focused training (often remote), covering scanner operation, data import, diagnostic interpretation, and report generation; and 30 days of technical support and software updates.

Kaplan says most shipyard staff can competently scan a propeller within an hour of hands-on use, with proficiency improving rapidly through guided practice.

In a market where delivery delays can erode margins and damage reputations, TrueProp offers shipbuilders a competitive advantage:

-

Control: In-house inspection eliminates reliance on external schedules.

-

Speed: Critical decisions can be made the same day the vessel is in dry dock.

-

Proof: Digital records enhance customer satisfaction and reduce disputes.

For Kaplan, the pitch to shipyards is straightforward: “If you can measure in place, you can avoid unnecessary removal, get ahead of problems before delivery, and give your customer a level of documentation that wasn’t possible before.”

Bottom Line: For shipbuilders, TrueProp isn’t just a measurement tool, it’s a way to protect the build schedule, reduce costs, and deliver vessels with verified performance. In a sector where precision equals profit, that’s a formula worth noting.

Propeller Inspection – Traditional vs. TrueProp

Time & Cost Impact for Shipyards

| Step | Traditional Inspection | Estimated Time | Estimated Cost | TrueProp In-Place Inspection | Estimated Time | Estimated Cost |

|---|---|---|---|---|---|---|

| 1. Prep & Removal | Union crew detaches propeller from shaft; requires rigging crew & supervisor. | 1–2 days | $5,000–$8,000 labor & equipment | Propeller remains on vessel; dry dock crew positions scanner. | 1–2 hours | $300–$500 labor |

| 2. Transport | Load propeller on truck & ship to off-site specialist. | 1 day | $1,500–$3,000 (trucking, insurance) | No transport needed. | 0 | $0 |

| 3. Off-Site Inspection | Manual probe-based measurements; data recorded by technician. | 1–2 days | $2,000–$4,000 | 3D scanning performed in situ; data captured directly to software. | 2–4 hours | Included in scanning labor |

| 4. Repair / Adjustment | If needed, repair performed at specialist facility. | 1–3 days | $3,000–$6,000 (plus materials) | Minor adjustments can be made in dry dock; major repairs scheduled with pre-measured data. | 0.5–2 days | $500–$2,000 (if required) |

| 5. Transport Back | Return propeller to shipyard. | 1 day | $1,500–$3,000 | Not applicable. | 0 | $0 |

| 6. Reinstallation | Union crew reinstalls propeller on shaft. | 1–2 days | $5,000–$8,000 | Not required unless prop removed for repair. | 0 | $0 |

| 7. Documentation | Manual report; possible transcription errors. | 0.5 day | Included | Automatic, standardized PDF report generated from scan data. | Minutes | Included |

-

Totals:

-

Traditional: 6–10 days | $18,000–$32,000

-

TrueProp: 0.5–2 days | $800–$2,500

-

Net Savings for Shipyard:

-

Time: 5–8 days faster

-

Cost: $17,000+ per inspection (when no major off-site repair is required)

Watch the full video interview with Adam Kaplan, CTO, TrueProp Software, LLC, to learn more about TrueProp and its value to ship and boat owners and shipbuilders: