New Products, Technologies & Systems

AI-powered Augmented Surveyor 3D

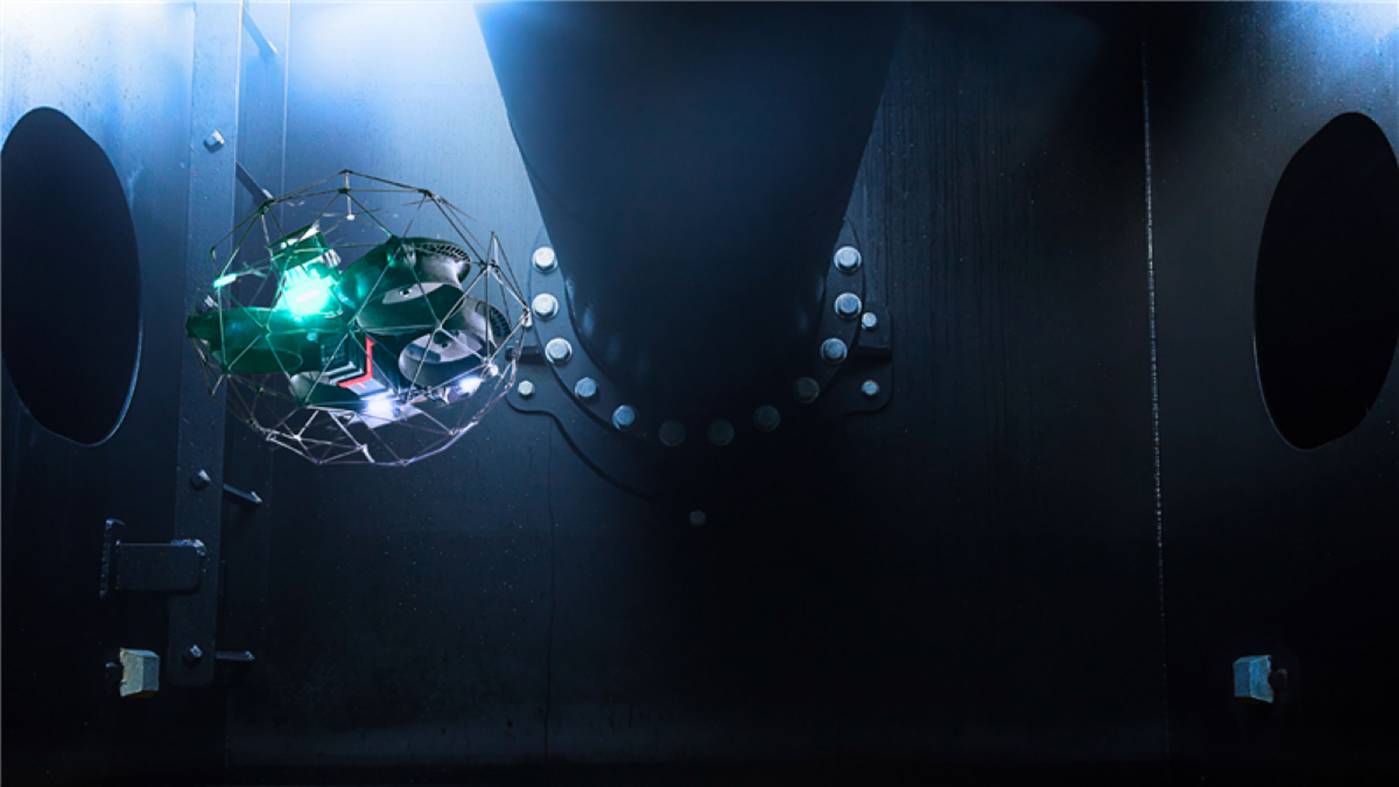

Bureau Veritas Marine & Offshore (BV) introduced its latest digital innovation, the Augmented Surveyor 3D (AGS 3D), an inspection tool leveraging artificial intelligence and machine learning to detect and localize structural anomalies on ships and offshore assets. The new solution was piloted successfully on a TotalEnergies-operated FPSO in West Africa. During the trial, drones captured extensive image and LiDAR data from two ballast tanks, which AGS 3D used to build a detailed 3D model, complete with AI-enhanced corrosion mapping. Following this success, TotalEnergies plans to extend AGS 3D to additional offshore assets.

AGS 3D is aiming to streamline inspection workflows by automating anomaly detection, defect localization, and corrosion analysis within a unified digital environment. By reducing human entry into confined spaces and expediting data processing, the solution improves both safety and efficiency across a range of marine sectors, including FPSOs, FSOs, floating wind platforms, and in-service ships.

The AGS 3D tool includes drone-based LiDAR scanning, AI-powered image analysis, automatic 3D defect localization, and a collaborative inspection platform.

“The Money Maker”:

MacGregor Gangway Solutions for Offshore Wind

Borrowing its experience in the offshore oil and gas business, MacGregor in 2018 launched an innovative gangway solution for the Offshore Wind industry. The gangways employ some critical technical features – permanent magnet motors and redundancy levels that exceed class requirements – that provide maritime operators maximum safety, efficiency & reliability. Bjørnar Berge, MacGregor, discusses with Maritime Reporter TV the value proposition of its gangway system in regards to how it extends the weather window, and revenue generation opportunities, for vessel owners and operators, as proven by operations in the Dogger Bank offshore wind field.

Warren Controls Valves

Warren Controls, a manufacturer of control valves and specialty fluid handling products, highlights the 1800 Series Heavy Globe Control Valves, designed for high-capacity applications across a range of industries. With rugged construction and precision control, the 1800 Series provides reliable performance in demanding environments.

The 1800 Series is available in connection sizes up to 12 inches, offering two-way balanced and unbalanced models, as well as three-way mixing and diverting configurations. Capable of handling extreme temperatures from -20°F to 800°F, high-pressure drops, and corrosive fluids, these valves are ideal for industries such as chemical processing, district energy, food and beverage, marine, power, and refining.

The 1800 Series features standard body materials of cast iron, steel, or stainless steel with multiple trim materials and port sizes. The equal percentage and linear plugs in the two-way valves and linear plugs in the three-way valves provide precise modulation of fluid flow.

Future-proof Ship Design by Deltamarin

Pre-Covid, 90% of Deltamarin’s ship design projects were based on conventional fuel, 10% on alternative fuel. Today, that script has completely flipped according to Esa Jokioinen and Mia Elg, Deltamarin, with approximately 95% of new project requests centered on hybrids and alternative fuels. Take a deep dive with Deltamarin’s Head of R&D and Sales Director for key tips and insights on planning a successful hybrid/alternative fuels ship design and construction project, start to finish.

Brine-Based Firefighting System

As EV-related fires continue to challenge the maritime industry, with incidents like the Morning Midas blaze in the North Pacific, operators are seeking more effective solutions. A new brine-based firefighting system, developed by Skansi Offshore and Knud E. Hansen offers an answer. The system is operational aboard Norrøna, sailing the world’s longest RoPAX route, and is scheduled for installation on two new RoRo vessels under construction.

Unlike traditional fire suppression methods, which act from the outside and often fail to extinguish the core fire, the brine system targets the battery directly from inside the vehicle. In the event of a fire, one window is penetrated, and cold, saturated brine is delivered directly into the cabin. This allows the fluid to pool around the battery compartment, rapidly cooling the cells, limiting oxygen exposure, suppressing flammable materials, and even short-circuiting and depowering the battery. In a full-scale fire test conducted in the Faroe Islands, the system extinguished a fully developed EV fire in under one hour.

Regal Rexnord: The Drivetrain Solution Specialist

Posted to Maritime Reporter TV (by Greg Trauthwein) on June 10, 2025

As the marine industry transitions from traditional diesel fuels to a myriad of hybrid and electric solutions, Regal Rexnord stands ready with a family of drivetrain solutions to achieve efficiency results.

Jotun Debuts Hull Performance Solutions 2.0

Jotun launched the next generation of its Hull Performance Solutions (HPS). Included in HPS 2.0 are two new products for different trades and environments, alongside the established and newly speed-loss verified SeaQuantum X200, technical service, hull condition management and performance guarantees.

HPS 2.0 will include four elements: tailored to trade, technical service from the industry's largest team of coatings advisors, intelligent hull condition management and credible performance guarantees.

Solutions tailored to specific needs are crucial as various trade patterns and operating environments each require specific coatings for optimal efficiency.

-

For predictable trades - SeaQuantum X200

-

For high fouling intensity trades - SeaQuantum XT

-

For unpredictable trades - SeaQuest Endura

Navtor eNavigation Evolution Stays Ahead of Regulation

The maritime industry is besieged with new regulations on multiple fronts, and the digitalization requirements are central to everything, from safe and efficient operations to decarbonization. On the exhibition floor at NorShipping 2025, Maritime Reporter TV connected with a trio of executives from Navtor to discuss the pace of change and how Navtor engages with industry to develop solutions that help ease the transition.

Hempel Launches First Silicone Hull Coating For Newbuilds

Hempel launched Hempaguard NB, a silicone hull coating designed specifically for newbuild vessels. For the first time, shipowners and shipyards can access Hempaguard’s fuel savings and fouling protection during the construction phase. Until now, applying silicone coatings during the newbuilding process has posed logistical challenges for shipowners. Conventional silicone solutions require controlled environments and are typically applied either pre-delivery or in post-delivery dry dockings, both of which cause delays and additional costs. This combines the performance of Hempaguard X7 with a new silicone topcoat, made specifically for newbuilds. It offers the same performance as Hempaguard X7, with nearly 5,000 applications and independently verified for its fuel-saving and decarbonization benefits. Shipowners can expect up to 20% fuel savings, only 1.2% average speed loss and 120 fouling-free idle days.

Clean Ship Hulls:

A Maritime Business Imperative

Driven by environmental regulations, keeping a clean hull is in vogue more than ever, but the business of maintaining a clean ship hull transcends checking off a box for regulators. Clean hulls are proven to reduce fuel consumption and emissions, and today there are a plethora of traditional diver based solutions and a long list of up and coming robotic solutions. Subsea Global Solutions offers both, and Karl Lander, SGS’ Environmental Services Director visited with Maritime Reporter TV to discuss the business case advantages. While final rules from the IMO will take years to formulate and enact, today ports are the drivers to modern hull cleaning and containment solutions.

ESAB Fast-Tracks Welding Efficiency, Effectiveness

As the shipyards struggle to effectively recruit and retain new welders to replace the aging workforce, attention increasingly turns to key system suppliers like ESAB, a global welding and cutting equipment. A host of continuous improvement across its welding portfolio – from its Warrior Edge to WeldCloud connectivity, RobustFeed wire feed and ECHO communications – all roads lead to improved efficiency and performance, with ease of training and use for the welder. Jeff Chittim, North America Senior Product Manager, ESAB, discusses latest updates with Maritime Reporter TV.

Viking Upgrades Undertun Commuter Ferry Evacuation System

Viking Life-Saving Equipment has expanded the capacity and capabilities of its unique Undertun commuter ferry evacuation system, as part of development work which also confirms the solution surpasses open sea performance requirements in SOLAS and the IMO code for High Speed Craft.

After acquiring all Undertun design, production and supply rights last year, VIKING has made two key upgrades to a system that is widely used in sheltered waters in Norway. It has added a 203-person capacity life raft to the 101- and 153-person units previously available, and a new activation capability that allows Undertun to be released with ease from the system, from the bridge, or even from shore.

Undertun is a self-contained gangway and inflatable life raft unit that can be fully integrated with a ship side shell door. Especially appealing for low height ships where crew numbers are limited, its accumulator-controlled gangway absorbs relative ship-raft motions, while separate "grip" and smooth surfaces allow walk-off or slide-off evacuation.

VIKING’s 203-person life raft is already recognized for performance equivalence to conventional lifeboats by the Danish Maritime Authority, Bahamas Maritime Authority and UK Maritime and Coastguard Agency in a separate application. As part of VIKING’s Undertun concept development, DNV has verified the entire system achieves SOLAS and HCC compliance outside sheltered waters.

Optimarin Launches Guardian BWTS

VOptimarin unveiled its latest ballast water treatment system, Optimarin Guardian. Designed to meet the evolving needs of vessel operators, Guardian combines high treatment efficiency with low power consumption and reduced lifecycle cost.

The launch is part of Optimarin’s broader strategy to respond to changing market dynamics through increased supply chain flexibility, expanded service offerings, and an enhanced technology portfolio following the acquisition of Hyde Marine’s UV BWTS technology.

The new system is optimized for large vessel segments but will also be available in a compact 60 cu. m./hr. version, making it suitable for smaller vessels such as fishing boats and yachts—an expansion that broadens Optimarin’s addressable market.

Guardian leverages Optimarin’s proven technology while improving energy efficiency. Early feedback from selected pilot installations has indicated measurable performance gains in both power usage and operational uptime.