Taming of the Engine Killers

Effectively Mitigating Heat & Vibration in the Engine Room

Keeping Machinery Heat & Vibration in Check

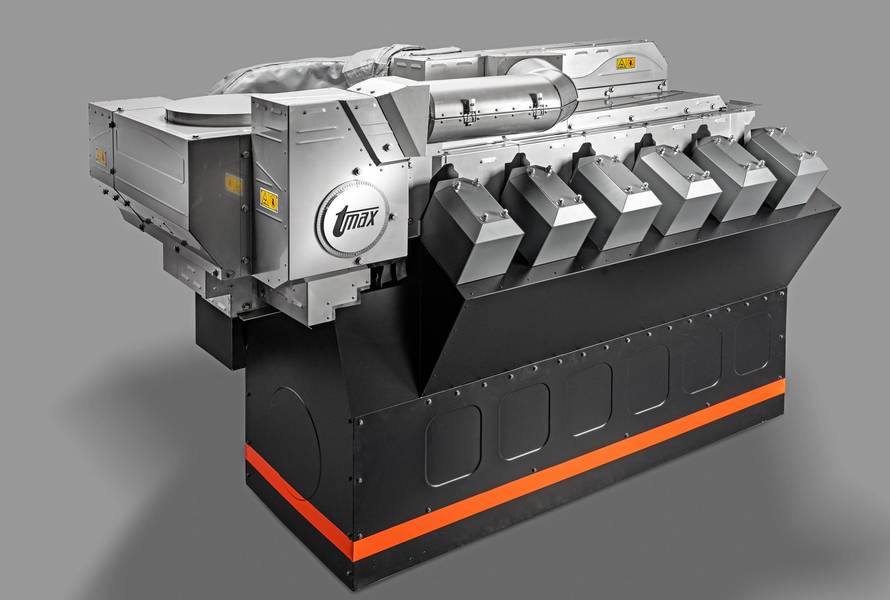

Thermal and acoustic insulation is the business of tmax Holding GmbH. Left: An engine with old, worn-out cladding; Right: An engine with new tmax cladding.

Steffen Cronauer, an

Thermal and acoustic insulation is the business of tmax Holding GmbH, a holding of six companies in Europe, USA and China with headquarters in Mannheim, Germany, a company of about 500 people working to provide engineered solutions to the automotive, on- and off-highway sectors, power sports vehicles, stationary power generation, ships, and oil platforms, both on land and at sea. For the marine industry, Thermamax is a solution provider for SOLAS-compliant insulation solutions for engine rooms. The company engineers and supplies insulation claddings for most of the leading engine and turbocharger OEMs. In addition, Thermamax is able to design, manufacture and install SOLAS-compliant retrofitting insulations also for engines that are already in service for a longer period of time and that eventually do not meet latest safety standards.

Something Old, Something New ...

According to Cronauer, the number one driver for Thermamax products in the maritime and offshore sectors is safety, and in fact it was the Deepwater Horizon accident that served as an inflection point with potential customers understanding that “sheet metal insulation cladding is the better product when it comes to safety onboard, whether it is a rig or a propulsion engine for a vessel.” According to IMO SOLAS the surface temperature of modern marine engines must not exceed 220°C. In addition, engine builders are striving for better fuel efficiency, mainly by increasing the engine`s power density what typically leads to higher exhaust gas temperatures. Due to higher charge air pressures even the area of the compressor outlet of the turbocharger becomes a concern in terms of surface temperatures. Consequently, every new engine has to be equipped with a highly efficient insulation system. “We also have to look at and consider the aftertreatment devices, as large SCR systems become more common on ships,” he said. “For example the aftertreamtment system is almost as big as the engine itself. They too are hot, they too must meet SOLAS requirements.”

While new engines are a central focus, the larger market opportunity comes in the retrofit sector, as there are many engines 20 years or older that could utilize an insulation retrofit, which spurred Thermamax to develop its Tmax-Retrofit.

Thermamax Engineered Solutions

While many may not put ‘insulation’ in the category of engineered solution, a stroll through the modern manufacting complex of Thermamax dispels that notion. It starts with the realization that the plant workers go about their business without masks, courtesy of a state-of-the-art air quality vaccum system which was installed and monitored regularly (Note: this visit was conducted pre-COVID-19).

There are many key factors to producing the bespoke engineered insulation solutions — from the latest laser cutting equipment to metal handling/bending machines, and, of course, the quality of the insulation materials themselves.

“The most important aspect is the grade of the material,” said Cronauer. “You can buy a 20 mm material for 10 Euros or for 7 Euros, but the fact is, this highest technical requirement for our material is not temperature, it’s vibration. Even the cheap stuff that you can use for the roof of your house can give you high temperature protection, but it’s the vibration that is a killer with a very bad influence on the lifetime of the insulation and the machinery.”

In this regard, for the marine sector Thermamax uses stainless steel and a stitched and woven insulation fabric that is designed to better withstand the pressures of heat, vibration and time.

The Thermamax retrofit solution starts with a 3D scan of the engine.

Over the years Thermamax has continued to invest in new machinery, for example laser cutting machines that today are five times more efficient than machines were 20 years ago, but at the same price point. And the advent of CFD simulation has allowed it to ensure that not only are its insulation solutions optimized for heat and vibration characteristics, but that they are engineered for ease of assembly and maintenance by unskilled workers; to maximize material use, “so maybe we don’t neet 2 mm thickness, maybe 1 mm is enough. And do we need 215 screws, or maybe only 120?”

Thermamax continually invests in R&D to test new materials, but to date stainless steel and fiber materials are still the go-to. “There is some movement (at the R&D departments that manufacture insulation material), but there hasn’t been a real breakthrough. For example, a cladding design without any fibre material. From a physics perspecitve, it is possible and it works perfectly on the test bench but the question is ... who will be the pioneer for this new design?”

But manufacturing in the marine sector is a low-volume affair for all, and Cronauer stress the importance of a skilled workforce to deliver consistent quality.

“Blue-collar workers in Germany go through an apprenticeship program that is three years long, certificate-based and teaches them how to work skillfully with metal (and other materials).”

As the maritime market moves increasingly to news fuels, hybrids and batteries, Thermamax evolves too, engineering unique solutions to address the need to manage heat and vibration. Recently Thermamax developed housings for battery modules to support electrification, beside others, for marine application. Also, on board ships electrification is becoming more and more important. Thermamax battery housings can be used for on-board energy storage systems,. Thermamax battery housings ensure effective fire protection and extend the battery range by balanced thermal management. But in regard to market guidance, Cronauer it was still too soon to tell how fast and how far these newer applications would move.

At the end of the day, the company is able to lean on the multiple markets it serves. “From the automotive side you can learn a lot of cost-efficiency, cost-engineering, secure processing,” said Cronauer. “From marine we learned a lot about combining multiple materials into a single function. This is a key factor in making Thermamax a leader in providing complex solutions.”

The Tmax-Retrofit

In the engine room temperatures are highest and reliable fire prevention is vital. As 3D details are often not available for older engines, retrofitting with SOLAS-compliant high-performance insulation systems has only been possible to a limited extent until now. With Tmax-Retrofit, older marine engines can now also be upgraded with high-temperature insulation systems which exceed SOLAS guidelines. The all-in-one package provides all services — from the preparation of the engine’s 3D profile to the thermography of the developed and installed insulation system — all from one source.

“We see retrofit opportunities, as there are many old ships with old engines with old insulation systems which are rotten and do not have any fire protection properties anymore,” said Steffen Cronauer. He noted that many engine manufacturers — Thermamax’s main customers — are not inspired to release a retrofit system for an engine released 25 years or older, and the decision to retrofit an insulation system requires conversation between the ship owner and the engine makers. “This is the biggest opportunity for us in the maritime sector. The offshore sector is interesting, too, dependent on the price of oil and their willingness to invest.”

1. A 3D-Scan of the engine to ensure the best fit of the exhaust gas and turbocharger cladding. Results of the scan are used as the basis for preparing digital 3D models.

2. Reverse Engineering: Based on the scanned 3D profile, Thermamax develops a CAD model of the engine. For this it first generates a polygon network in STL format from the available data. This is converted into standard geometries and free-form surfaces. From these attributed surface models and own on-site photos, we can then create a CAD model in the STEP or IGES format.

3. Design and Simulation: Now starts the classic design process. On the basis of a 0D/1D thermal calculation Thermamax defines material and thickness of the insulation. The detailled constrution is made in Creo, a specialized software. The result is a durable exhaust gas/turbocharger cladding which reliably lowers the maximum surface temperature below 220°C and even below 100 °C, depending on requirements.

4. Manufacture: First, Thermamax produces a prototype. Which will be test-installed on a mock-up in order to guaranty best fit later on the engine. The individual Tmax-Insulation Cladding is now ready to use and can be installed.

5. Installation: Thermamax installs the exhaust gas/turbocharger cladding — first the prototype — on your engine.

6. Thermography: To ensure that the new insulation system performs as required, Thermamax performs a thermography test.

Tmax offers a SOLAS-check in order to provide a profound assessment to the vessel responsible. Regardless of whether the customer buys the insulation, if necessary, at Thermamax or renews it on his own. And for Tmax-Insulation cladding, the company offers a regular maintenance service during which the insulation is checked against SOLAS requirements and takes care of the production and replacement of the installation if hotspots are detected.