Vessels

New Deliveries, Contracts & Concepts

Maryland Pilots Get High-Speed Launch from Gladding-Hearn Shipbuilding

The Association of Maryland Pilots has taken delivery of its fifth Chesapeake Class launch from Gladding-Hearn Shipbuilding, Duclos Corporation since 2002. With a deep-V hull designed by Ray Hunt Design, the new all-aluminum high-speed launch measures 52.6- x 16.8 ft. with a 4.8-ft. draft. Powered by twin Volvo Penta D16, EPA Tier 3-certified diesel engines, each producing 750 Bhp at 1900 rpm. The vessel’s top speed is over 27 knots. A Humphree interceptor trim control system, with its Automatic Trim Optimization, is installed at the transom.

The engines turn 5-blade Bruntons NiBrAl propellers via ZF500-1-A gearboxes. The launch is equipped with a Northern Lights 12 kW genset.

The vessel’s wheelhouse, with a small trunk, is amidship on a flush deck. With electrically heated, forward-leaning front windows, the wheelhouse is outfitted with five Norsap shock-mitigating reclining seats, a baggage rack, and three weathertight doors. The forecastle includes a porta-potty, a split upholstered settee/bunk, and a custom storage rack for immersion suits and other safety gear. The vessels’ interior is heated and cooled by two 16,000 Btu reverse-cycle HVAC units, in addition to electric heaters located in the wheelhouse and forecastle.

Outside the wheelhouse, heated decks and handrails prevent ice accumulation. A Harken TR-31 safety rail system was installed on the wheelhouse handrail. An aft wheelhouse ladder leads to hinged boarding platforms on the roof. A control station at the transom features a hydraulically powered J-Basket rescue system, capable of retrieving a pilot from the water to the main deck in less than 10 seconds with a single operator, said Duclos.

Vessel Data and Specifications

-

Vessel Name SEVERN

-

Hull Type Deep-V monohull

-

Owner Association of Maryland Pilots

-

Builder Gladding-Hearn Shipbuilding, Duclos Corporation

-

Architect Ray Hunt Design

-

Length 52.6 feet

-

Beam 16.8 feet

-

Draft 4.8 feet

-

Date keel laid April 1, 2024

-

Date launched August 11, 2025

-

Date delivered August 18, 2025

-

Main Engines (2) Volvo Penta D16, EPA Tier 3-certified diesel engines, each 641 Bhp at 1800 rpm

-

Engine supplier Power Products Systems, Wakefield, MA

-

Gears (2) ZF500-1-A gearboxes

-

Propellers (2) 5-blade Bruntons NiBrAl

-

Genset 12 kW Northern Lights M843NW3G

-

Steering system Seastar Optimus system with a 24 VDC dual pump hydraulic power unit (HPU). Each helm in the wheelhouse and at the transom is fitted with an electronic helm unit and SS destroyer-type wheel. A CanTrak display is located on the wheelhouse console for system programming and rudder-angle indication. Installed at the transom is a Humphree trim-tab control system with an Automatic Trim Optimization feature.

-

Radar (2) Furuno TZTL16

-

VHF (2) Furuno 4800 VHF radios, (2) 8' Shakespeare antennas, (2) Furuno 4800A handsets

-

GPS (2) Furuno GP330B GPS/WAAS Sensor

-

AIS Furuno FA-170 AIS, 4' Shakespeare VHF/AIS antenna

-

Depth sounder Furuno

-

Compass 5" Richie compass, Furuno SC33 satellite compass

-

Loud hailer/siren Furuno LH5000

-

Thermal camera FLIR M 332 Thermal Camera

-

Fuel 800 U.S. gal

-

Sewage holding tank Porta Potty 5 U.S. gal

-

Crew size Captain & 1 deckhand

-

Speed (loaded) 27 knots

-

HVAC (2) Dometic 16,000 Btu

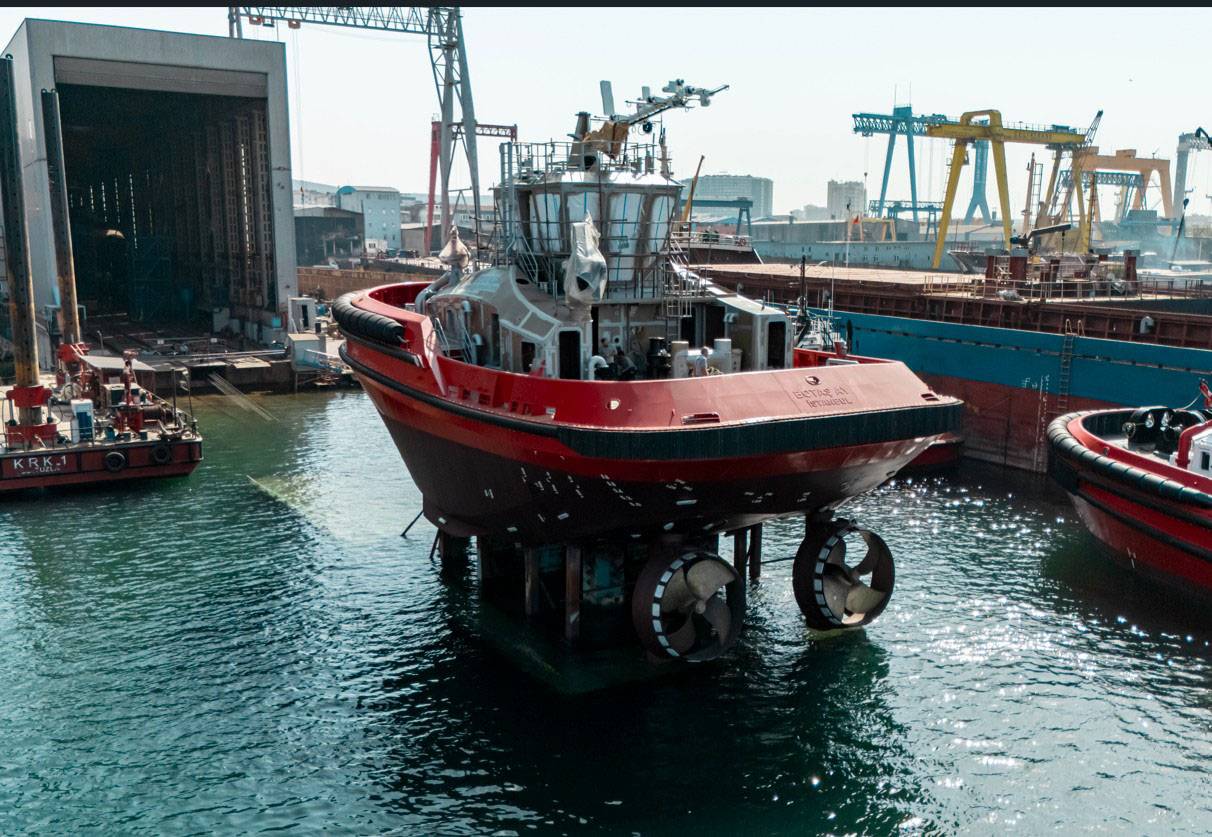

Sanmar Launches Third Electric Tugboat

Sanmar launched the third of four fully electric ElectRA Series tugs that it is building for BOTAŞ, Turkiye’s state-owned crude oil and natural gas pipeline and trading company. All four of the tugboats are based on the ElectRA 2500SX design from Canadian naval architects Robert Allan Ltd. The first was launched on July 5 this year, and the second on August 9. ElectRA Series tugs are exclusive to Sanmar and are the result of the company’s ongoing collaboration with Robert Allan Ltd and battery provider Corvus Energy to build a new generation of eco-friendly low and no-emission tugs, by using alternative fuels and innovative technological advances. With a battery capacity of 5,085 kWh each of the BOTAŞ tugs can achieve 70 tons of bollard pull and a speed of 12 knots. They have accommodation for a crew of up to eight people, and include backup diesel gensets for fire-fighting and extended endurance. The tugs to be named BOTAŞ HİLAL, BOTAŞ BAYRAK, BOTAŞ AY, and BOTAŞ YILDIZ will measure 25.4m overall, with a 12.8m beam, 5.2m depth, and a maximum draft of 5.8m. They are designed to carry out a wide range of tasks, including escort duties.

Dominican Navy Commissions Near Coastal Patrol Vessel (NCPV)

The Dominican Navy received its second 85 x 19.5-ft. welded aluminum Near Coastal Patrol Vessel (NCPV), built by Metal Shark. Christened ARCTURUS, CG-114 keeps with the Dominican tradition of naming military vessels after constellations and celestial bodies. The delivery of ARCTURUS CG-114 follows the delivery of the Dominican Navy’s BETELGEUSE CG-102 in 2020. The vessel was acquired by the Dominican Republic under a $54m U.S. Navy Foreign Military Sales contract awarded to Metal Shark to produce up to 13 85-foot Defiant-class patrol craft for U.S. partner nations in support of regional defense initiatives. ARCTURUS CG-114 is the seventh NCPV to be delivered. The NCPV is a monohull vessel premised on the 2606 Standardized Patrol vessel, which has been optimized by Metal Shark to suit the requirements of the NCPV mission.

Powered by twin 1,600-hp Caterpillar C-32 marine diesel engines turning fixed-pitch Michigan Wheel propellers through Twin Disc MGX-6599 transmissions, the NCPV achieves speeds in excess of 25 knots. The vessel has been designed for missions of up to six days at sea, supporting an operating crew of 10.

To maximize versatility, the NCPV carries a 5.6-meter Metal Shark-built aluminum RIB, powered by twin 50-horsepower Mercury four-stroke outboards.

Ice-Class Tugboat Victoria

A new chapter in Arctic towage begins as Victoria, a newly delivered ice-class tugboat built by Damen Shipyards, has entered service in the Swedish port of Luleå. This is a milestone not only for the port, but also for Steerprop, a provider of propulsion systems for demanding marine environments, as it represents the first deployment of its Steerprop CRP (Contra-Rotating Propeller) azimuth propulsors in the tugboat segment.

Victoria is the first vessel in Damen’s new Azimuth Stern Drive (ASD) Tug 3413 ICE design — a class purpose-built for Arctic operations. Designed to deliver consistent performance in ice-covered waters, the tug is equipped with two Steerprop SP 60 CRP ECO propulsors, each rated at 3,700 kW and certified to 1A Super ice class. These advanced propulsion units combine pushing and pulling propellers within a single system, delivering superior maneuverability, ice performance, and energy efficiency in both harsh ice conditions and open water.

Located on the northern Gulf of Bothnia, the Port of Luleå is Sweden’s “gateway to the Arctic.” With increasing cargo traffic and occasional cruise ship visits, its operational requirements demand reliable, high-performance tugs capable of year-round service. The new Damen tug meets this challenge, designed to maintain 8 knots through 1.1-meter thick floe ice or 3 knots through 1.1 meter first-year level ice.

The ASD Tug 3413 ICE is engineered for versatility and performance, achieving a maximum speed of 14.1 knots and a bollard pull of 72.8 tons ahead and 68.5 tons astern. The 34-meter-long, 13-meter-wide tugs were built at Damen’s Song Cam Shipyard in Vietnam.

SunStone Completes Infinity Class Series

SunStone Maritime Group A/S delivered the seventh and final vessel in this first series of newbuilds, the Douglas Mawson. The delivery took place at China Merchants Heavy Industry in Haimen, China, on September 9, 2025.

Named after Sir Douglas Mawson, the Australian geologist and Antarctic explorer whose work was central to the study of the polar regions, it is the third Infinity vessel to go to Aurora Expeditions, following Greg Mortimer and Sylvia Earle.

Measuring 104.4 x 18.4m with a 5.3m draft, the vessel offers a passenger capacity of 170, supported by a crew capacity of 102. Notably, the vessel is Ice Class 1A and Polar Class 6 certified, allowing it to operate in both warm and cold waters. Douglas Mawson features the X-Bow by Ulstein Design & Solutions, and is equipped with Safe Return to Port, virtual anchoring, and zero speed stabilizers. The vessel provides a wide range of amenities, including a swimming pool, bar and restaurants, lounges, a boutique, gym, spa, and sauna, all while maintaining an exclusive atmosphere for the guests.

The vessel represents an international collaboration between Norwegian naval architects (Ulstein), Swedish-American interior designers (Tomas Tillberg Design USA), Finnish interior contractors (Makinen), and a Chinese Shipyard (CMHI).

CSOV Delivered to Bernhard Schulte Offshore

Bernhard Schulte Offshore (BSO) took delivery of its newest Commissioning Service Operation Vessel (CSOV), built by Ulstein Verft in Norway. The vessel, named Windea Clausius, was christened on September 4, 2025.

“The new Windea Clausius completes our modern offshore fleet which now comprises five state-of-the-art vessels,” says Matthias Müller, Managing Director at Bernhard Schulte Offshore. “The new ship and its sister vessel Windea Curie, which has been already delivered in June, are characterized by their innovative design features focused on reliability, operability, flexibility, and sustainability.”

Windea Clausius features two sterns and azimuth propellers at both fore and aft, ensuring optimal performance in Dynamic Positioning (DP) operations and enhancing fuel efficiency. Regardless of whether the vessel is facing towards or away from the weather, it maintains excellent operability and flexibility. With the Ulstein’s TWIN X-STERN design, the ship can minimize motion—critical for safe gangway operations as well as crew and personnel well-being.

Equipped with a large, height-adjustable, centrally located walk-to-work gangway and elevator tower for personnel and cargo transfers, the vessel also includes a 3D motion-compensated crane for offshore lifts of up to five tons. Onboard logistics are optimized with spacious storage areas and stepless access to offshore installations. In addition, Windea Clausius features a height-adjustable boat landing system that allows for safe and stepless transfer of personnel and equipment between the CSOV and smaller crew transfer vessels — an important safety aspect especially while operating within offshore wind farms.

Windea Clausius offers up to 90 cabins with windows for charterers’ offshore personnel. In total, there are 111 cabins providing comfortable living conditions for up to 132 individuals. With hybrid battery propulsion and methanol fuel readiness, the vessel is designed for low-carbon operations and is ideally suited for both operations and maintenance (O&M) and construction support roles, particularly in harsh offshore environments.

The newbuilding is named after the German physicist Rudolf Clausius whose work on thermodynamics established fundamental principles for understanding energy transformations, including wind energy. The naming continues the tradition of naming BSO’s offshore vessels after outstanding personalities and scientists, as the Windea La Cour, Windea Leibniz, Windea Jules Verne, and Windea Curie.