Boats

Launches | Deliveries | Contracts | Concepts

Meet OX: World’s Most Powerful Sub-26-ft. Tractor Tug

Silverback Marine, [Port of Tacoma, WA] is currently building what is expected to be the world’s most powerful non-Subchapter M (Sub 26-ft.) tractor tug for the Department of Defense.

Distinct from other “truckable tugs”, the OX series from Silverback has a projected bollard pull capacity of up to 7 tons, enabling operators to reduce operational cost both in terms of manpower and support infrastructure.

Powered by twin Cummins diesel engines, the tug not only maintains traditional tractor tug design lines but is also powered by Schottel SRP100 Azimuth thrusters. Each prop has a diameter of 33.5-in., and 216KW input power.

“Silverback spent a little over three years refining the design of the OX, and a huge part of this was identifying key vendors that we could be confident in,” said Ian Gracey, CEO of Silverback Marine. “Part of our approach was to consult not only highly experienced and seasoned tug captains, but also mechanics servicing tugs.”

After completing the concept of intention and design, Silverback Marine contracted Elliot Bay Design Group of Seattle, WA to perform the necessary engineering, hydrostatics, and lofting of the vessel.

“The core purpose of this mini tug is to bring real, useable towing capacity to the truckable tug market. With the twin azimuth drives, captains can enjoy “big tug characteristics” in a very compact package, without the headache of costly Subchapter M requirements. The heavy-gauge aluminum hull, protected by Schuyler fendering, reduces weight and corrosion costs compared to traditional steel hulls, and the compact size allows haul out with conventional travel lifts.

Great Lakes Launches Subsea Rock Installation Vessel

Great Lakes Dredge & Dock Corporation launched the first U.S. flagged, Jones Act-compliant subsea rock installation (SRI) vessel, named Acadia, at Hanwha Philly Shipyard. Acadia is engineered to transport and precisely install up to 20,000 metric tons of rock on the seabed.

The rock provides critical scour protection for subsea infrastructure including subsea cables for power transmission, telecommunications cables, oil and gas pipelines and subsea structures and offshore wind turbine foundations, preventing erosion caused by waves and currents and mechanical impacts from equipment and vessels. The delivery of the vessel is expected early in 2026.

In addition to supporting the U.S. domestic market, Great Lakes has expanded its market focus for the vessel to work in the international offshore energy development markets.

“Acadia is the centerpiece of our offshore energy growth strategy and will begin operations immediately upon leaving the shipyard,” said Lasse Petterson, President and CEO, Great Lakes. “The launch of the Acadia marks a major milestone for our Offshore Energy business. Upon delivery, the Acadia will start her journey towards New York for the installation of rock for the Empire Wind I offshore wind farm and continue working on the U.S. East Coast on contracted work through the end of 2026.

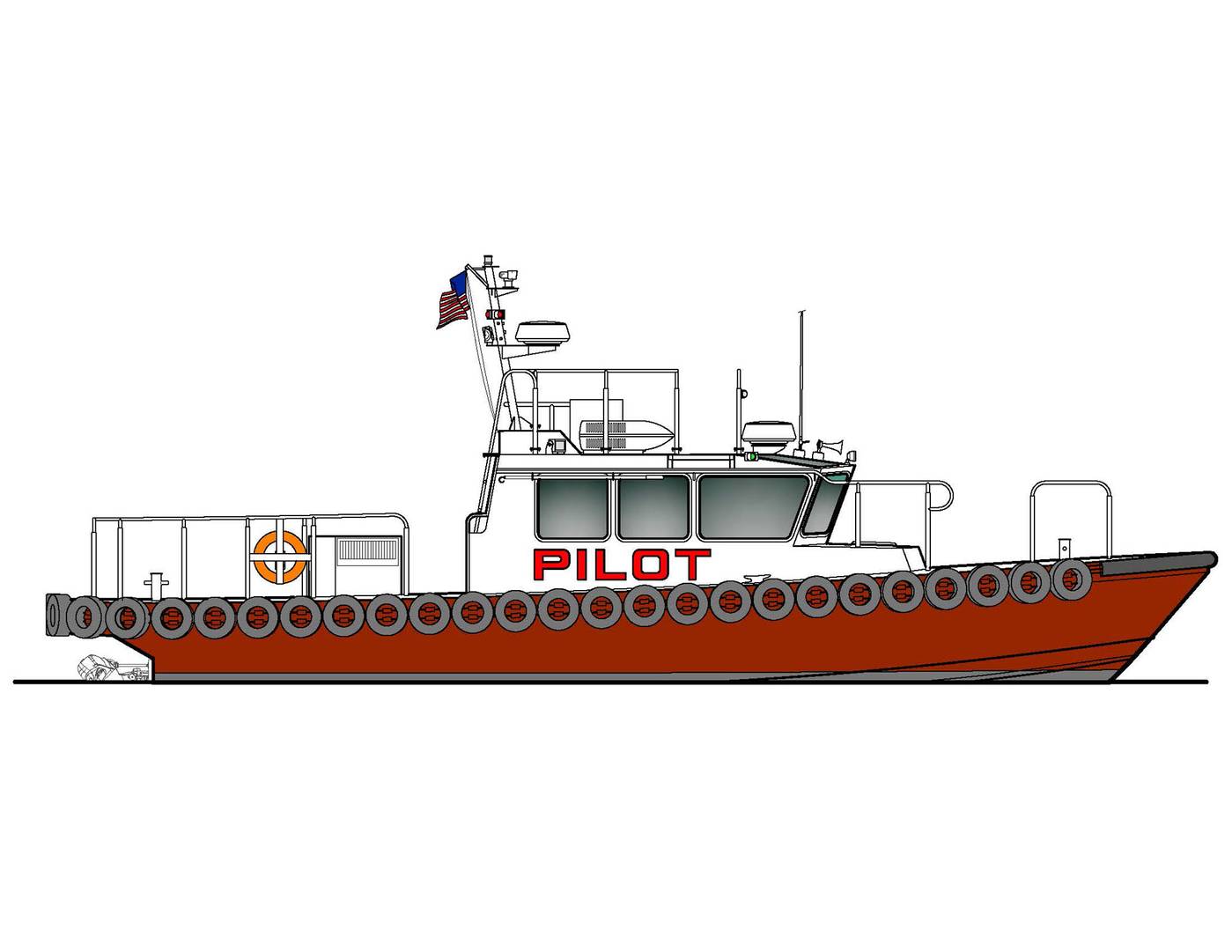

Delta Pilots Order Two High-Speed Launches from Gladding-Hearn

Delta Launch Services, a launch company operating on the Mississippi River, ordered a pair of new class of pilot boats from Gladding-Hearn Shipbuilding, Duclos Corporation. The Venice Class launches follow a long history of six larger pilot boats built for the Delta Launch Services by the Somerset, Mass., shipyard. Delivery is scheduled for 2027.

The custom 44-footer is based on the shipyard’s Resilient class; the design is optimized for performing launch services on the Mississippi River. “The lower Mississippi can be a harsh operating environment. The silty water is abrasive, with a lot of debris and ship wakes. Ship boardings are done at transit speed in a narrow channel with no opportunity to make a lee. This will be a simple, robust launch propelled by water jets and with a stable platform like our offshore pilot boats,” said Peter Duclos, President, Gladding-Hearn Shipbuilding.

The new launch measures 44.3-ft. overall, with a beam of 13.1-ft. and a shoal draft of 2.5-ft. The all-aluminum Ray Hunt Design Deep-V hull will be powered by twin Caterpillar C-9.3 EPA Tier 3-compliant diesel engines, each delivering 476 Bhp at 2,300 rpm and a top speed of 34 knots. The engines will be connected to Twin Disc gearboxes and propelled by twin Hamilton HTX-30 waterjets. An Interceptor trim control system will be installed at the transom.

The wheelhouse will be flush-mounted aft of amidships and outfitted with five Norsap shock-mitigating seats. The laminated forward-facing wheelhouse windows are electrically heated and equipped with retractable sunshades. A roof-mounted, 15,000 btu air conditioning unit will cool the wheelhouse while at the dock. Two engine-driven 24,000 btu units will cool and heat the wheelhouse while underway.

American Patriot Christened in Newport

American Cruise Lines christened American Patriot in Newport, Rhode Island, the first ship in the company’s new Patriot Class—a fleet of new 130-passenger ships designed for exclusively cruising the U.S. market. Patriot Class sister ships, American Pioneer, American Maverick, and American Ranger are soon to launch later this year and into 2026.

The American Patriot accommodates just 130 guests. It features 4 decks, private balcony staterooms and suites, a chart room, spacious lounges (including a top deck lounge with a walking track), plus a main restaurant, casual café, and fitness center. The company’s new Patriot Class ships and all 25 small ships in the fleet offer world-class amenities, unusual for ships of their size.

Bollinger Tapped to Modify Rocket Lab's Neutron Landing Platform

Rocket Lab Corporation awarded a contract to Bollinger Shipyards to support the build out of Rocket Lab’s ocean landing platform for its Neutron reusable rocket. Modification and fit-out of Rocket Lab technology to its 400-ft.-long landing platform named ‘Return On Investment’ has begun and is taking place at Bollinger Shipyards, primarily at its shipyard in Amelia, La., with delivery of the vessel to Rocket Lab expected in early 2026.

Reusability is key to Rocket Lab’s development of Neutron. To meet the increasing demand for regular and reliable launch to space for large single satellites, multi-satellite constellation deployment, and high assurance national security missions, Rocket Lab expects to quickly scale Neutron and double its launch capacity annually once it enters service – with “Return On Investment” integral to that effort. Rocket Lab’s development of recovery infrastructure in Louisiana builds upon the Company’s existing U.S. expansion plans for Neutron’s operations and development, with “Return On Investment” to be operated out of the U.S. East Coast to support timely delivery and return of Neutron rockets to its launch site on Wallops Island, Virginia.

Tamarack: New Cement Carrier for the Great Lakes

Holland Shipyards Group, in collaboration with Eureka Shipping and SMT Shipping, delivered the cement carrier Tamarack at Holland Shipyards Group’s yard in Hardinxveld-Giessendam.

Tamarack is a 12,500-DWT self-discharging cement carrier designed specifically for the Great Lakes region in Canada. Built to replace two older vessels, Tamarack offers equivalent transport capacity in a more compact and efficient platform. The vessel is equipped with diesel-electric propulsion, featuring four generator sets, two 360-degree rudder propellers, and a powerful bow thruster for optimal maneuverability. It also includes four dedicated cement cargo holds with a total capacity of 10,700 cu. m., supported by high-efficiency loading and discharging systems.

Tamarack’s design includes fuel-efficient engines capable of running on HVO biofuel and two rudder propellers that provide full-circle thrust, improving docking and harbor maneuversTo reduce operational noise, the ship has been fitted with extensive noise insulation and silencers. Moreover, the vessel is prepared for shore power connectivity, enabling zero-emission operations in ports as infrastructure evolves.

RIBCRAFT Patrol Boat to Coventry Police Department

The city of Coventry, RI, recently took delivery of a 19-ft. RIBCRAFT 5.85 for its police department, a specialized RIB that enhances patrol and response capabilities while providing a safe platform for public safety efforts during on-water events.

Located in the Pawtuxet River Valley, the department primarily operates on Johnson’s Pond, but needed a vessel that could easily be towed to other waterways in town as needed. RIBCRAFT worked with the Police Chief and Lieutenant to understand the department’s needs and outfit the 5.85 to meet mission requirements. Based on a previous Rhode Island DEM Division of Law Enforcement contract, the new patrol boat is well equipped and answers the need for a reliable marine presence in the community.

The RIB features a center console with front bench seat, operator leaning post, full size windscreen mounted to a T-top, fore and aft tow posts, engine crash rail and keel guard. Powered by a 115HP Yamaha outboard, the boat reaches speeds in excess of 42mph, equipped with a black multi-chambered heavy-duty Hypalon tube complete with bow reinforcing, boarding wear patches, and custom reflective lettering. The electronics package includes a blue LED law enforcement light bar, Whelen Hailer/Siren, 360 degree scene lighting, Garmin GPS and State radio.

Metal Shark Delivers Fireboat

Metal Shark delivered a new 40 x 12-ft. welded aluminum monohull pilothouse fireboat to Tampa Fire Rescue. Designed in-house by Metal Shark and built at the company’s Jeanerette, La., production facility, the new vessel is the first of two next-generation 38 Defiant NXT fireboats being built for the Department.

Powered by triple 300 hp Yamaha outboards with HelmMaster controls and joystick operational capability, the vessel is purpose-built to enable Tampa Fire Rescue, which is charged with the responsibility of primary fire suppression in and about Port Tampa Bay and the surrounding industrialized area, the 42-mile Tampa shipping channel, and all waters of Tampa Bay from downtown Tampa to the barrier island of Egmont Key.

It features Metal Shark’s NXT EMS response cabin equipped with three SHOXS shock-mitigating seats, an EMS bench, dedicated officer/communications and firefighting control stations, and comprehensive gear storage for EMS, fire suppression, dive, and rescue operations. Equipped with a Honeywell CBRNE (chemical, biological, radiological, nuclear, and high-yield explosive) detection system and an HDT cabin filtration and pressurization package, the vessel is fully prepared for HAZMAT and CBRNE response missions at the Port or at sea.

Firefighting capabilities are anchored by a Darley fire pump drawing from a fully flooded Seachest and delivering 1,500 GPM via NFPA piping and electronically controlled valves to a remote-operated monitor. This configuration enables long-range throw for ship-to-ship and ship-to-shore operations. Additional features include dual 2.5” handline discharges, a 5” Storz hydrant discharge for supplying land-based apparatus, and a 40-gallon quick-fill foam injection system for AFFF firefighting capability.

SAAM, Enap Debut Latin America's First Electric Tug

SAAM christened Trapananda, reported to be the first electric tugboat in Latin America. Thanks to a strategic partnership with Enap, the electric tug will operate in one of the southernmost terminals in the world, Puerto Chacabuco, in the Aysén Region, supporting ship berthing and deberthing operations.

Trapananda Technical Specs

The tug measures 25 x 13m and brings 70 tons of bollard pull capacity, enabling it to assist large vessels in challenging harbor conditions. The craft is equipped with two, 2,100-kW electric azimuth thrusters and is powered by a 3,616-kWh capacity lithium-ion battery, distributed in two compartments. Its design, created by Robert Allan Ltd. and built by the Sanmar shipyard in Turkey, is optimized to reduce hull resistance while maximizing energy efficiency. The batteries are remotely monitored by the manufacturer from Norway and have an estimated life of 10 years.

The tug was christened Trapananda in honor of the ancient name of Chilean Patagonia, a remote, untamed land covered with dense jungles that represented an unexplored and challenging territory for the first Spanish explorers.

"The arrival of the Trapananda marks a before and after for our industry. We are moving decidedly toward cleaner, more efficient and environmentally friendly operations,” said Macario Valdés, CEO, SAAM. “This project is a vision for the future: we are developing solutions that not only tow and assist ships, but also mobilizing a shift towards a truly sustainable logistics chain. On this path, we have found in Enap a partner with a shared vision.”

“This new tugboat, the result of a fruitful partnership with SAAM, demonstrates that when the public and private sectors work together decisively, they can advance on complex challenges like decarbonization. This step is a concrete sign that we can accelerate the energy transition through collaboration and action," added Gloria Maldonado, Chairwoman, Enap.

RAstar 3200-W Tugboat Delivered to Egyptian Navy

The Ras Alhekma terminal support/escort tug has been delivered to the Egyptian Navy in Alexandria, Egypt, built at Alexandria Shipyard, the first of series of five that are being built in the yard.

The RAstar escort series tug features unique sponsoned hull form developed exclusively by Robert Allan Ltd. All provide high bollard pull, power, maneuverability with the Ras Alhekma receiving positive feedback during trials from the owner including low noise levels of the tug due to noise treatments designed by this office and applied by the shipyard.

The tug measures 32.7 x 13.2m with a 5m depth and a gross tonnage of 498. Classed by BV, sea trial results showed that the 86 tonnes bollard pull and speed of 14.1 knots surpassed the owner’s performance requirements for this design.